Page 139 - Mechanical Engineers Reference Book

P. 139

3/22 Microprocessors, instrumentation and control

- signals

--

- Trans- Telemetry Data

processing -

7 ducer - - ;

signals

1 il

-

Computer/ -

controller

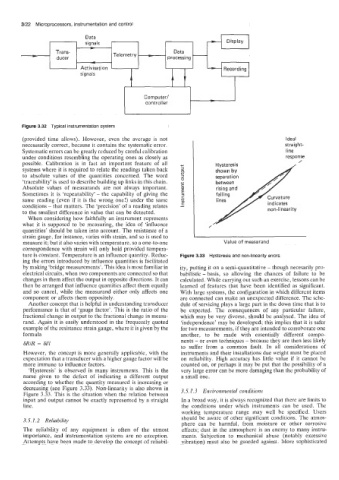

Figure 3.32 Typical instrumentation system

(provided time allows). However, even the average is not Ideal

necesssarily correct, because it contains the systematic error. straight-

Systematic errors can be greatly reduced by careful calibration line

under conditions resembling the operating ones as closely as response

possible. Calibration is in fact an important feature of all Hysteresis /

systems where it is required to relate the readings taken back shown by

to absolute values of the quantities concerned. The word

‘traceability’ is used to describe building up links in this chain.

Absolute values of measurands are not always important.

Sometimes it is ‘repeatability’ -the capability of giving the

same reading (even if it is the wrong one!) under the same

conditions - that matters. The ‘precision’ of a reading relates

to the smallest difference in value that can be detected.

When considering how faithfully an instrument represents

what it is supposed to be measuring, the idea of ‘influence

quantities’ should be taken into account. The resistance of a

strain gauge, for instance, varies with strain, and so is used to

measure it; but it also varies with temperature, so a one-to-one Value of measurand

correspondence with strain will only hold provided tempera-

ture is constant. Temperature is an influence quantity. Reduc- Figure 3.33 Hysteresis and non-linearity errors

ing the errors introduced by influence quantities is facilitated

by making ‘bridge measurements’. This idea is most familiar in ity, putting it on a semi-quantitative -though necesarily pro-

electrical circuits, when two components are connected so that babilistic - basis, so allowing the chances of failure to be

changes in them affect the output in opposite directions. It can calculated. While carrying out such an exercise, lessons can be

then be arranged that influence quantities affect them equally learned of features that have been identified as significant.

and so cancel, while the measurand either only affects one With large systems, the configuration in which different items

component or affects them oppositely. are connected can make an unexpected difference. The sche-

Another concept that is helpful in understanding transducer dule of servicing plays a large part in the down time that is to

performance is that of ‘gauge factor’. This is the ratio of the be expected. The consequences of any particular failure,

fractional change in output to the fractional change in measu- which may be very diverse, should be analysed. The idea of

rand. Again it is easily understood in the frequently quoted ‘independence’ may be developed; this implies that it is safer

example of the resistance strain gauge, where it is given by the for two measurements, if they are intended to corroborate one

formula another, to be made with essentially different compo-

nents - or even techniques - because they are then less likely

6RIR = 6111

to suffer from a common fault. In all considerations of

However, the concept is more generally applicable, with the instruments and their installations due weight must be placed

expectation that a transducer with a higher gauge factor will be on reliability. High accuracy has little value if it cannot be

more immune to influence factors. counted on, or perhaps it may be put that the possibility of a

‘Hysteresis’ is observed in many instruments. This is the very large error can be more damaging than the probability of

name given to the defect of indicating a different output a small one.

according to whether the quantity measured is increasing or

decreasing (see Figure 3.33). Non-linearity is also shown in 3.5.1.3 Environmental conditions

Figure 3.33. This is the situation when the relation between

input and output cannot be exactly represented by a straight In a broad way, it is always recognized that there are limits to

line. the conditions under which instruments can be used. The

working temperature range may well be specified. Users

should be aware of other significant conditions. The atmos-

3.5.1.2 Reliability phere can be harmful, from moisture or other corrosive

The reliability of any equipment is often of the utmost effects; dust in the atmosphere is an enemy to many instru-

importance, and instrumentation systems are no exception. ments. Subjection to mechanical abuse (notably excessive

Attempts have been made to develop the concept of reliabil- vibration) must also be guarded against. More sophisticated