Page 75 - Mechanical Engineers Reference Book

P. 75

2/16 Electrical and electronics principles

Coil voltage output

(b)

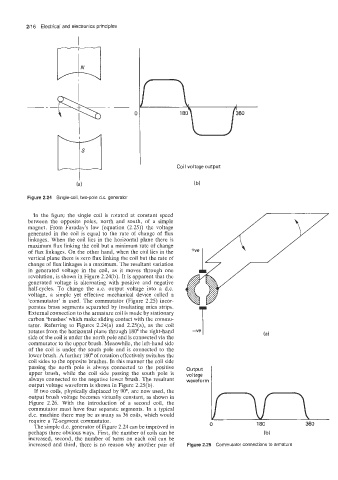

Figure 2.24 Single-coil, two-pole d.c. generator

In the figure the single coil is rotated at constant speed

between the opposite poles, north and south, of a simple

magnet. From Faraday's law (equation (2.25)) the voltage

generated in the coil is equal to the rate of change of flux

linkages. When the coil lies in the horizontal plane there is

maximum flux linking the coil but a minimum rate of change

of flux linkages. On the other hand, when the coil lies in the

vertical plane there is zero flux linking the coil but the rate of

change of flux linkages is a maximum. The resultant variation

in generated voltage in the coil, as it moves through one

revolution, is shown in Figure 2.24(b). It is apparent that the

generated voltage is alternating with positive and negative

half-cycles. To change the a.c. output voltage into a d.c.

voltage, a simple yet effective mechanical device called a

'commutator' is used. The commutator (Figure 2.25) incor-

porates brass segments separated by insultating mica strips.

External connection to the armature coil is made by stationary -ve T

carbon 'brushes' which make sliding contact with the commu-

tator. Referring to Figures 2.24(a) and 2.25(a), as the coil

rotates from the horizontal plane through 180" the right-hand

side of the coil is under the north pole and is connected via the

commutator to the upper brush. Meanwhile, the left-hand side

of the coil is under the south pole and is connected to the

lower brush. A further 180" of rotation effectively switches the

coil sides to the opposite brushes. In this manner the coil side

passing the north pole is always connected to the positive output

upper brush, while the coil side passing the south pole is voltage

always connected to the negative lower brush. The resultant wavefo r rn

output voltage waveform is shown in Figure 2.25(b).

If two coils, physically displaced by 90°, are now used, the

output brush voltage becomes virtually constant, as shown in

Figure 2.26. With the introduction of a second coil, the

commutator must have four separate segments. In a typical

d.c. machine there may be as many as 36 coils, which would

require a 72-segment commutator.

The simple d.c. generator of Figure 2.24 can be improved in 0 180 360

perhaps three obvious ways. First, the number of coils can be (b)

increased, second, the number of turns on each coil can be

increased and third, there is no reason why another pair of Figure 2.25 Commutator connections to armature