Page 403 - Mechanical Engineers' Handbook (Volume 2)

P. 403

394 Basic Control Systems Design

(s) K T

(9)

V(s) (Ls R)(Is c)

where R and L are the resistance and inductance of the field circuit and K is the torque

T

constant. No back emf exists in this motor to act as a self-braking mechanism.

Two-phase ac motors can be used to provide a low-power, variable-speed actuator. This

motor type can accept the ac signals directly from LVDTs and synchros without demodu-

lation. However, it is difficult to design ac amplifier circuitry to do other than proportional

action. For this reason, the ac motor is not found in control systems as often as dc motors.

The transfer function for this type is of the form of Eq. (9).

An actuator especially suitable for digital systems is the stepper motor, a special dc

motor that takes a train of electrical input pulses and converts each pulse into an angular

displacement of a fixed amount. Motors are available with resolutions ranging from about 4

steps per revolution to more than 800 steps per revolution. For 36 steps per revolution, the

motor will rotate by 10 for each pulse received. When not being pulsed, the motors lock

in place. Thus, they are excellent for precise positioning applications, such as required with

printers and computer tape drives. A disadvantage is that they are low-torque devices. If the

input pulse frequency is not near the resonant frequency of the motor, we can take the output

rotation to be directly related to the number of input pulses and use that description as the

motor model.

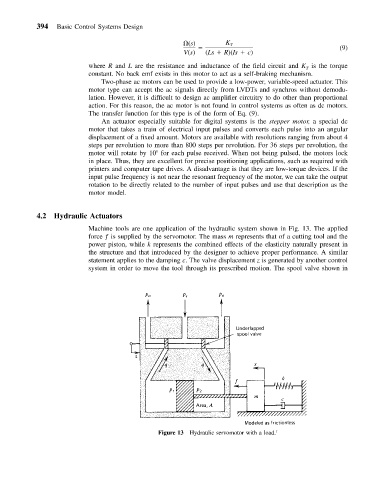

4.2 Hydraulic Actuators

Machine tools are one application of the hydraulic system shown in Fig. 13. The applied

force ƒ is supplied by the servomotor. The mass m represents that of a cutting tool and the

power piston, while k represents the combined effects of the elasticity naturally present in

the structure and that introduced by the designer to achieve proper performance. A similar

statement applies to the damping c. The valve displacement z is generated by another control

system in order to move the tool through its prescribed motion. The spool valve shown in

Figure 13 Hydraulic servomotor with a load. 1