Page 563 - Mechanical Engineers' Handbook (Volume 2)

P. 563

554 Servoactuators for Closed-Loop Control

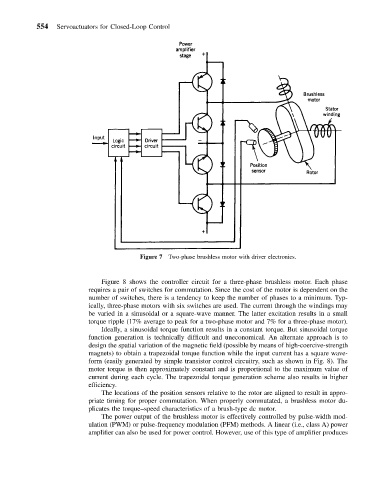

Figure 7 Two-phase brushless motor with driver electronics.

Figure 8 shows the controller circuit for a three-phase brushless motor. Each phase

requires a pair of switches for commutation. Since the cost of the motor is dependent on the

number of switches, there is a tendency to keep the number of phases to a minimum. Typ-

ically, three-phase motors with six switches are used. The current through the windings may

be varied in a sinusoidal or a square-wave manner. The latter excitation results in a small

torque ripple (17% average to peak for a two-phase motor and 7% for a three-phase motor).

Ideally, a sinusoidal torque function results in a constant torque. But sinusoidal torque

function generation is technically difficult and uneconomical. An alternate approach is to

design the spatial variation of the magnetic field (possible by means of high-coercive-strength

magnets) to obtain a trapezoidal torque function while the input current has a square wave-

form (easily generated by simple transistor control circuitry, such as shown in Fig. 8). The

motor torque is then approximately constant and is proportional to the maximum value of

current during each cycle. The trapezoidal torque generation scheme also results in higher

efficiency.

The locations of the position sensors relative to the rotor are aligned to result in appro-

priate timing for proper commutation. When properly commutated, a brushless motor du-

plicates the torque–speed characteristics of a brush-type dc motor.

The power output of the brushless motor is effectively controlled by pulse-width mod-

ulation (PWM) or pulse-frequency modulation (PFM) methods. A linear (i.e., class A) power

amplifier can also be used for power control. However, use of this type of amplifier produces