Page 156 - Mechanics of Microelectromechanical Systems

P. 156

3. Microsuspensions 143

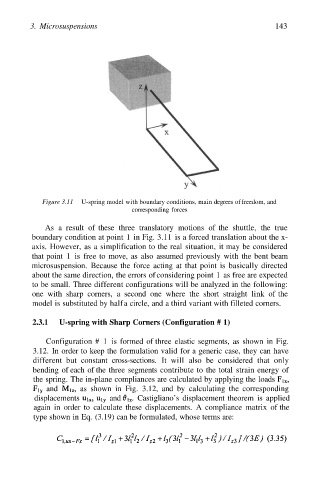

Figure 3.11 U-spring model with boundary conditions, main degrees of freedom, and

corresponding forces

As a result of these three translatory motions of the shuttle, the true

boundary condition at point 1 in Fig. 3.11 is a forced translation about the x-

axis. However, as a simplification to the real situation, it may be considered

that point 1 is free to move, as also assumed previously with the bent beam

microsuspension. Because the force acting at that point is basically directed

about the same direction, the errors of considering point 1 as free are expected

to be small. Three different configurations will be analyzed in the following:

one with sharp corners, a second one where the short straight link of the

model is substituted by half a circle, and a third variant with filleted corners.

2.3.1 U-spring with Sharp Corners (Configuration # 1)

Configuration # 1 is formed of three elastic segments, as shown in Fig.

3.12. In order to keep the formulation valid for a generic case, they can have

different but constant cross-sections. It will also be considered that only

bending of each of the three segments contribute to the total strain energy of

the spring. The in-plane compliances are calculated by applying the loads

and as shown in Fig. 3.12, and by calculating the corresponding

displacements and Castigliano’s displacement theorem is applied

again in order to calculate these displacements. A compliance matrix of the

type shown in Eq. (3.19) can be formulated, whose terms are: