Page 351 - A Practical Guide from Design Planning to Manufacturing

P. 351

Microprocessor Packaging 321

3

3 years. As transistors have scaled to smaller dimensions, that power is

concentrated in a smaller area. High-performance processors may produce

2

as much as 100 W/cm . Without proper cooling, many processors could

quickly reach temperatures that would cause permanent damage.

Heat is never destroyed; it can only be moved. A refrigerator does not

create cold, it merely moves heat from its interior to the exterior. Leave

the refrigerator door open and in the end the room will get warmer

from the heat of the refrigerator’s motor. The ability of the package and

system to cool the processor is therefore determined by how easily heat

can move. This is typically measured as thermal resistance and has an

important impact on the performance of the processor.

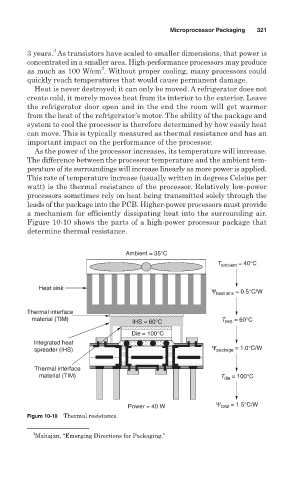

As the power of the processor increases, its temperature will increase.

The difference between the processor temperature and the ambient tem-

perature of its surroundings will increase linearly as more power is applied.

This rate of temperature increase (usually written in degrees Celsius per

watt) is the thermal resistance of the processor. Relatively low-power

processors sometimes rely on heat being transmitted solely through the

leads of the package into the PCB. Higher-power processors must provide

a mechanism for efficiently dissipating heat into the surrounding air.

Figure 10-10 shows the parts of a high-power processor package that

determine thermal resistance.

Ambient = 35°C

T ambient = 40°C

Heat sink

Ψ heat sink = 0.5°C/W

Thermal interface

material (TIM) T = 60°C

IHS = 60°C IHS

Die = 100°C

Integrated heat

spreader (IHS) Ψ package = 1.0°C/W

Thermal interface

material (TIM) T die = 100°C

Ψ = 1.5°C/W

Power = 40 W total

Figure 10-10 Thermal resistance.

3

Mahajan, “Emerging Directions for Packaging.”