Page 354 - A Practical Guide from Design Planning to Manufacturing

P. 354

324 Chapter Ten

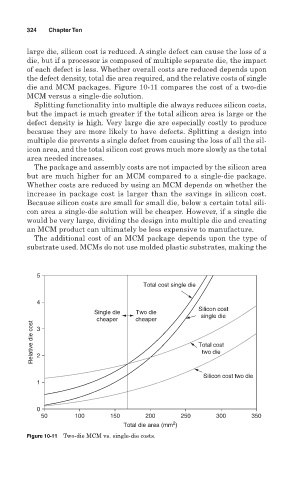

large die, silicon cost is reduced. A single defect can cause the loss of a

die, but if a processor is composed of multiple separate die, the impact

of each defect is less. Whether overall costs are reduced depends upon

the defect density, total die area required, and the relative costs of single

die and MCM packages. Figure 10-11 compares the cost of a two-die

MCM versus a single-die solution.

Splitting functionality into multiple die always reduces silicon costs,

but the impact is much greater if the total silicon area is large or the

defect density is high. Very large die are especially costly to produce

because they are more likely to have defects. Splitting a design into

multiple die prevents a single defect from causing the loss of all the sil-

icon area, and the total silicon cost grows much more slowly as the total

area needed increases.

The package and assembly costs are not impacted by the silicon area

but are much higher for an MCM compared to a single-die package.

Whether costs are reduced by using an MCM depends on whether the

increase in package cost is larger than the savings in silicon cost.

Because silicon costs are small for small die, below a certain total sili-

con area a single-die solution will be cheaper. However, if a single die

would be very large, dividing the design into multiple die and creating

an MCM product can ultimately be less expensive to manufacture.

The additional cost of an MCM package depends upon the type of

substrate used. MCMs do not use molded plastic substrates, making the

5

Total cost single die

4

Silicon cost

Single die Two die

cheaper cheaper single die

Relative die cost 2 Total cost

3

two die

Silicon cost two die

1

0

50 100 150 200 250 300 350

2

Total die area (mm )

Figure 10-11 Two-die MCM vs. single-die costs.