Page 131 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 131

HYBRID AND MCM TECHNOLOGIES 111

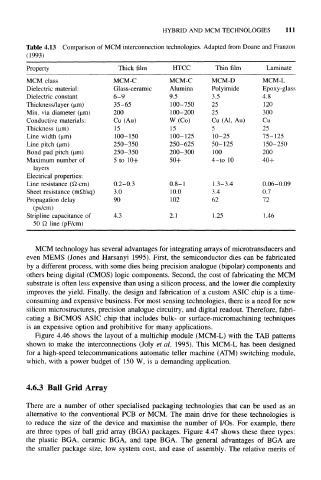

Table 4.13 Comparison of MCM interconnection technologies. Adapted from Doane and Franzon

(1993)

Property Thick film HTCC Thin film Laminate

MCM class MCM-C MCM-C MCM-D MCM-L

Dielectric material: Glass-ceramic Alumina Polyimide Epoxy-glass

Dielectric constant 6-9 9.5 3.5 4.8

Thickness/layer (um) 35-65 100-750 25 120

Min. via diameter (urn) 200 100-200 25 300

Conductive materials: Cu (Au) W(Co) Cu (Al, Au) Cu

Thickness (am) 15 15 5 25

Line width (um) 100-150 100-125 10-25 75-125

Line pitch (um) 250-350 250-625 50-125 150-250

Bond pad pitch (um) 250-350 200-300 100 200

Maximum number of 5 to 10+ 50+ 4-to 10 40+

layers

Electrical properties:

Line resistance (£2 -cm) 0.2-0.3 0.8-1 1.3-3.4 0.06-0.09

Sheet resistance (mfi/sq) 3.0 10.0 3.4 0.7

Propagation delay 90 102 62 72

(ps/cm)

Stripline capacitance of 4.3 2.1 1.25 1.46

50 Q line (pF/cm)

MCM technology has several advantages for integrating arrays of microtransducers and

even MEMS (Jones and Harsanyi 1995). First, the semiconductor dies can be fabricated

by a different process, with some dies being precision analogue (bipolar) components and

others being digital (CMOS) logic components. Second, the cost of fabricating the MCM

substrate is often less expensive than using a silicon process, and the lower die complexity

improves the yield. Finally, the design and fabrication of a custom ASIC chip is a time-

consuming and expensive business. For most sensing technologies, there is a need for new

silicon microstructures, precision analogue circuitry, and digital readout. Therefore, fabri-

cating a BiCMOS ASIC chip that includes bulk- or surface-micromachining techniques

is an expensive option and prohibitive for many applications.

Figure 4.46 shows the layout of a multichip module (MCM-L) with the TAB patterns

shown to make the interconnections (Joly et al. 1995). This MCM-L has been designed

for a high-speed telecommunications automatic teller machine (ATM) switching module,

which, with a power budget of 150 W, is a demanding application.

4.6.3 Ball Grid Array

There are a number of other specialised packaging technologies that can be used as an

alternative to the conventional PCB or MCM. The main drive for these technologies is

to reduce the size of the device and maximise the number of I/Os. For example, there

are three types of ball grid array (BGA) packages. Figure 4.47 shows these three types:

the plastic BGA, ceramic BGA, and tape BGA. The general advantages of BGA are

the smaller package size, low system cost, and ease of assembly. The relative merits of