Page 126 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 126

106 STANDARD MICROELECTRONIC TECHNOLOGIES

Cover film

Adhesive | Etch

firm firm mm nrm

Copper

Adhesive

Base film

Single-sided flex-printed wiring

Cover film

Adhesive

Copper nrm mm mm mm

Adhesive Etch

Base film :> Y///////////////////////////A

Adhesive mm mm mm mm

Copper Laminate

Y///////////////////////////A

Adhesive Double-sided flex-printed wiring

Cover film

Cover film"

Adhesive

Copper

Adhesive mm rmn mm nrm

Base film

Adhesive Etch nrm mrn rmn mm

Copper

Adhesive Laminate

Cover film mm mm mm mm

Adhesive y/////////////////////////zm

Copper Multilayer flex-printed wiring

Adhesive

Base film

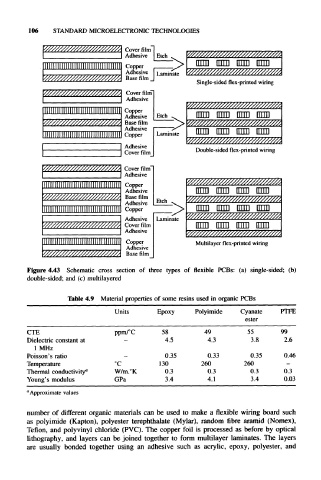

Figure 4.43 Schematic cross section of three types of flexible PCBs: (a) single-sided; (b)

double-sided; and (c) multilayered

Table 4.9 Material properties of some resins used in organic PCBs

Units Epoxy Polyimide Cyanate PTFE

ester

CTE ppm/°C 58 49 55 99

Dielectric constant at - 4.5 4.3 3.8 2.6

1 MHz

Poisson's ratio - 0.35 0.33 0.35 0.46

Temperature °C 130 260 260 -

Thermal conductivity a W/m.°K 0.3 0.3 0.3 0.3

Young's modulus GPa 3.4 4.1 3.4 0.03

a

Approximate values

number of different organic materials can be used to make a flexible wiring board such

as polyimide (Kapton), polyester terephthalate (Mylar), random fibre aramid (Nomex),

Teflon, and polyvinyl chloride (PVC). The copper foil is processed as before by optical

lithography, and layers can be joined together to form multilayer laminates. The layers

are usually bonded together using an adhesive such as acrylic, epoxy, polyester, and