Page 125 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 125

PRINTED CIRCUIT BOARD TECHNOLOGIES 105

- Copper interconnect

Dielectric

-Plated through hole

(b) L —Dielectric Copper interconnect

Blind via —\ /-Buried via

Dielectric-/ Copper interconnect-

(c) Plated through hole

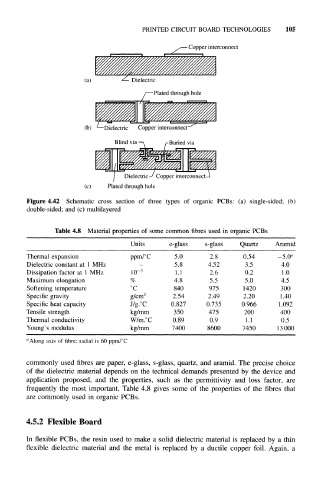

Figure 4.42 Schematic cross section of three types of organic PCBs: (a) single-sided; (b)

double-sided; and (c) multilayered

Table 4.8 Material properties of some common fibres used in organic PCBs

Units e-glass s-glass Quartz Aramid

Thermal expansion ppm/°C 5.0 2.8 0.54 –5.0 a

Dielectric constant at 1 MHz - 5.8 4.52 3.5 4.0

Dissipation factor at 1 MHz 10 –3 1.1 2.6 0.2 1.0

Maximum elongation % 4.8 5.5 5.0 4.5

Softening temperature °c 840 975 1420 300

Specific gravity g/cm 3 2.54 2.49 2.20 1.40

Specific heat capacity J/g.°c 0.827 0.735 0.966 1.092

Tensile strength kg/mm 350 475 200 400

Thermal conductivity W/m.°C 0.89 0.9 1.1 0.5

Young's modulus kg/mm 7400 8600 7450 13000

a

Along axis of fibre; radial is 60 ppm/°C

commonly used fibres are paper, e-glass, s-glass, quartz, and aramid. The precise choice

of the dielectric material depends on the technical demands presented by the device and

application proposed, and the properties, such as the permittivity and loss factor, are

frequently the most important. Table 4.8 gives some of the properties of the fibres that

are commonly used in organic PCBs.

4.5.2 Flexible Board

In flexible PCBs, the resin used to make a solid dielectric material is replaced by a thin

flexible dielectric material and the metal is replaced by a ductile copper foil. Again, a