Page 120 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 120

MONOLITHIC MOUNTING 101

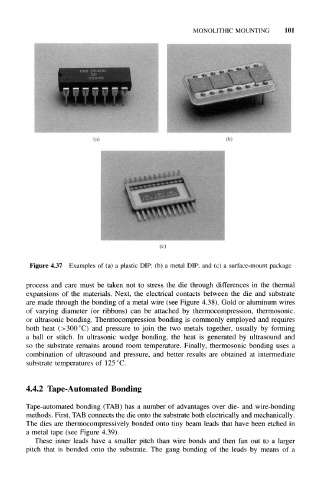

Figure 4.37 Examples of (a) a plastic DIP; (b) a metal DIP; and (c) a surface-mount package

process and care must be taken not to stress the die through differences in the thermal

expansions of the materials. Next, the electrical contacts between the die and substrate

are made through the bonding of a metal wire (see Figure 4.38). Gold or aluminum wires

of varying diameter (or ribbons) can be attached by thermocompression, thermosonic,

or ultrasonic bonding. Thermocompression bonding is commonly employed and requires

both heat (>300°C) and pressure to join the two metals together, usually by forming

a ball or stitch. In ultrasonic wedge bonding, the heat is generated by ultrasound and

so the substrate remains around room temperature. Finally, thermosonic bonding uses a

combination of ultrasound and pressure, and better results are obtained at intermediate

substrate temperatures of 125°C.

4.4.2 Tape-Automated Bonding

Tape-automated bonding (TAB) has a number of advantages over die- and wire-bonding

methods. First, TAB connects the die onto the substrate both electrically and mechanically.

The dies are thermocompressively bonded onto tiny beam leads that have been etched in

a metal tape (see Figure 4.39).

These inner leads have a smaller pitch than wire bonds and then fan out to a larger

pitch that is bonded onto the substrate. The gang bonding of the leads by means of a