Page 123 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 123

MONOLITHIC MOUNTING 103

Die or chip

Al or Au wire

Die-bond material

Figure 4.38 Die- and wire-bonding technique

-TAB lead

— Chip

• Die-bond material

\

Substrate

Figure 4.39 Tape-automated bonding technique

hot thermode produces a faster throughput than wire bonding. Moreover, the reduced

inductance of a probe means that the devices can be AC-tested.

The disadvantages of TAB include the relatively high cost of the process and the need

for a large device footprint. This problem is overcome in flip-chip mounting.

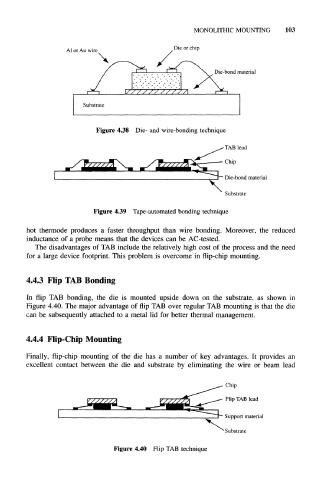

4.4.3 Flip TAB Bonding

In flip TAB bonding, the die is mounted upside down on the substrate, as shown in

Figure 4.40. The major advantage of flip TAB over regular TAB mounting is that the die

can be subsequently attached to a metal lid for better thermal management.

4.4.4 Flip-Chip Mounting

Finally, flip-chip mounting of the die has a number of key advantages. It provides an

excellent contact between the die and substrate by eliminating the wire or beam lead

Chip

Flip TAB lead

Support material

Substrate

Figure 4.40 Flip TAB technique