Page 119 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 119

100 STANDARD MICROELECTRONIC TECHNOLOGIES

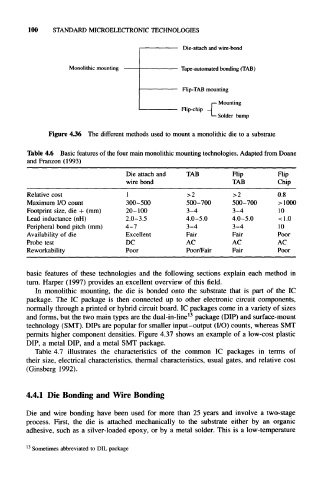

Die-attach and wire-bond

Monolithic mounting Tape-automated bonding (TAB)

Flip-TAB mounting

Mounting

Flip-chip —I

Solder bump

Figure 4.36 The different methods used to mount a monolithic die to a substrate

Table 4.6 Basic features of the four main monolithic mounting technologies. Adapted from Doane

and Franzon (1993)

Die attach and TAB Flip Flip

wire bond TAB Chip

Relative cost 1 >2 >2 0.8

Maximum I/O count 300-500 500-700 500-700 1000

Footprint size, die + (mm) 20-100 3-4 3-4 10

Lead inductance (nH) 2.0-3.5 4.0-5.0 4.0-5.0 <1.0

Peripheral bond pitch (mm) 4-7 3-4 3-4 10

Availability of die Excellent Fair Fair Poor

Probe test DC AC AC AC

Reworkability Poor Poor/Fair Fair Poor

basic features of these technologies and the following sections explain each method in

turn. Harper (1997) provides an excellent overview of this field.

In monolithic mounting, the die is bonded onto the substrate that is part of the IC

package. The IC package is then connected up to other electronic circuit components,

normally through a printed or hybrid circuit board. IC packages come in a variety of sizes

13

and forms, but the two main types are the dual-in-line package (DIP) and surface-mount

technology (SMT). DIPs are popular for smaller input-output (I/O) counts, whereas SMT

permits higher component densities. Figure 4.37 shows an example of a low-cost plastic

DIP, a metal DIP, and a metal SMT package.

Table 4.7 illustrates the characteristics of the common IC packages in terms of

their size, electrical characteristics, thermal characteristics, usual gates, and relative cost

(Ginsberg 1992).

4.4.1 Die Bonding and Wire Bonding

Die and wire bonding have been used for more than 25 years and involve a two-stage

process. First, the die is attached mechanically to the substrate either by an organic

adhesive, such as a silver-loaded epoxy, or by a metal solder. This is a low-temperature

13

Sometimes abbreviated to DIL package