Page 127 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 127

PRINTED CIRCUIT BOARD TECHNOLOGIES 107

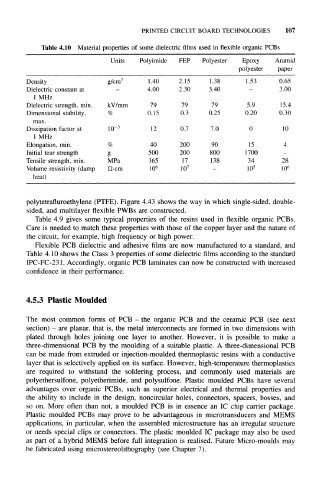

Table 4.10 Material properties of some dielectric films used in flexible organic PCBs

Units Polyimide FEP Polyester Epoxy Aramid

polyester paper

Density g/cm 3 1.40 2.15 1.38 1.53 0.65

Dielectric constant at 4.00 2.30 3.40 - 3.00

1 MHz

Dielectric strength, min. kV/mm 79 79 79 5.9 15.4

Dimensional stability, % 0.15 0.3 0.25 0.20 0.30

max.

Dissipation factor at 10 –3 12 0.7 7.0 0 10

1 MHz

Elongation, min. % 40 200 90 15 4

Initial tear strength g 500 200 800 1700 -

Tensile strength, min. MPa 165 17 138 34 28

Volume resistivity (damp Q-cm 10 6 10 7 - 10 5 10 6

heat)

polytetrafluroethylene (PTFE). Figure 4.43 shows the way in which single-sided, double-

sided, and multilayer flexible PWBs are constructed.

Table 4.9 gives some typical properties of the resins used in flexible organic PCBs.

Care is needed to match these properties with those of the copper layer and the nature of

the circuit, for example, high frequency or high power.

Flexible PCB dielectric and adhesive films are now manufactured to a standard, and

Table 4.10 shows the Class 3 properties of some dielectric films according to the standard

IPC-FC-231. Accordingly, organic PCB laminates can now be constructed with increased

confidence in their performance.

4.5.3 Plastic Moulded

The most common forms of PCB - the organic PCB and the ceramic PCB (see next

section) - are planar, that is, the metal interconnects are formed in two dimensions with

plated through holes joining one layer to another. However, it is possible to make a

three-dimensional PCB by the moulding of a suitable plastic. A three-dimensional PCB

can be made from extruded or injection-moulded thermoplastic resins with a conductive

layer that is selectively applied on its surface. However, high-temperature thermoplastics

are required to withstand the soldering process, and commonly used materials are

polyethersulfone, polyetherimide, and polysulfone. Plastic moulded PCBs have several

advantages over organic PCBs, such as superior electrical and thermal properties and

the ability to include in the design, noncircular holes, connectors, spacers, bosses, and

so on. More often than not, a moulded PCB is in essence an IC chip carrier package.

Plastic moulded PCBs may prove to be advantageous in microtransducers and MEMS

applications, in particular, when the assembled microstructure has an irregular structure

or needs special clips or connectors. The plastic moulded IC package may also be used

as part of a hybrid MEMS before full integration is realised. Future Micro-moulds may

be fabricated using microstereolithography (see Chapter 7).