Page 138 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 138

118 SILICON MICROMACHINING: BULK

Some of these etch processes have already been used as a standard technology in the

microelectronics industry, for example, RIE (Chapter 2).

In addition to an etch process, bulk micromachining often utilises wafer bonding and

buried oxide-layer technologies. However, the use of the latter in bulk micromachining

is still in its infancy.

This chapter describes the commonly used bulk-micromachining processes and gives

2

a set of worked examples that illustrate the applications of each one, or a combination,

of these important processes. The discussion includes the important topics of etch-stops

and wafer-to-wafer bonding.

5.2 ISOTROPIC AND ORIENTATION-DEPENDENT WET

ETCHING

Wet chemical etching is widely used in semiconductor processing. It is used for lapping

and polishing to give an optically flat and damage-free surface and to remove contami-

nation that results from wafer handling and storing. Most importantly, it is used in the

fabrication of discrete devices and integrated circuits (ICs) of relatively large dimensions

to delineate patterns and to open windows in insulating materials. The basic mechanisms

for wet chemical etching of electronic materials were described in Section 2.4. It was

also mentioned that most of the wet-etching processes are isotropic, that is, unaffected by

crystallographic orientation.

However, some wet etchants are orientation-dependent, that is, they have the property

of dissolving a given crystal plane of a semiconductor much faster than other planes (see

Table 5.1). In diamond and zinc-blende lattices, the (111) plane is more closely packed

than the (100) plane and, hence, for any given etchant, the etch-rate is expected to be

slower.

A commonly used orientation-dependent etch for silicon consists of a mixture of potas-

sium hydroxide (KOH) in water and isopropyl alcohol. The etch-rate is about 2.1 um/min

for the (110) plane, 1.4 urn/min for the (100) plane, and only 0.003 um/min for the (111)

plane at 80 °C; therefore, the ratio of the etch rates for the (100) and (110) planes to the

(111) plane are very high at 400:1 and 600:1, respectively.

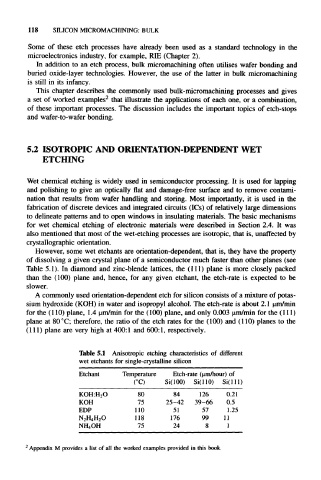

Table 5.1 Anisotropic etching characteristics of different

wet etchants for single-crystalline silicon

Etchant Temperature Etch-rate (jim/hour) of

(°C) Si(100) Si(110) Si(111)

KOH:H 2O 80 84 126 0.21

KOH 75 25-42 39-66 0.5

EDP 110 51 57 1.25

N 2H 4H 2O 118 176 99 11

NH 4OH 75 24 8 1

' Appendix M provides a list of all the worked examples provided in this book.