Page 139 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 139

ISOTROPIC AND ORIENTATION-DEPENDENT WET ETCHING 119

(111)

- - Resist

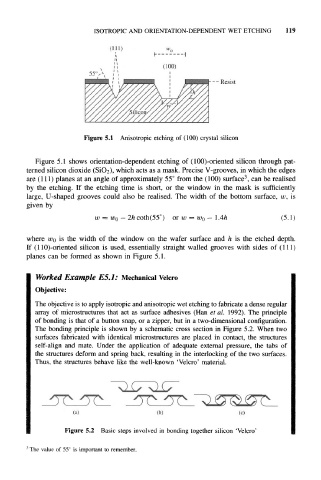

Figure 5.1 Anisotropic etching of (100) crystal silicon

Figure 5.1 shows orientation-dependent etching of (100)-oriented silicon through pat-

terned silicon dioxide (SiO2), which acts as a mask. Precise V-grooves, in which the edges

3

are (111) planes at an angle of approximately 55° from the (100) surface , can be realised

by the etching. If the etching time is short, or the window in the mask is sufficiently

large, U-shaped grooves could also be realised. The width of the bottom surface, w, is

given by

w = WQ — 2h coth(55°) or w = WQ — 1.4h (5.1)

where WQ is the width of the window on the wafer surface and h is the etched depth.

If (110)-oriented silicon is used, essentially straight walled grooves with sides of (111)

planes can be formed as shown in Figure 5.1.

Worked Example E5.1: Mechanical Velcro

Objective:

The objective is to apply isotropic and anisotropic wet etching to fabricate a dense regular

array of microstructures that act as surface adhesives (Han et al. 1992). The principle

of bonding is that of a button snap, or a zipper, but in a two-dimensional configuration.

The bonding principle is shown by a schematic cross section in Figure 5.2. When two

surfaces fabricated with identical microstructures are placed in contact, the structures

self-align and mate. Under the application of adequate external pressure, the tabs of

the structures deform and spring back, resulting in the interlocking of the two surfaces.

Thus, the structures behave like the well-known 'Velcro' material.

(a) (b) (c)

Figure 5.2 Basic steps involved in bonding together silicon 'Velcro'

' The value of 55° is important to remember.