Page 200 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 200

180 MICROSTEREOLITHOGRAPHY FOR MEMS

and therefore post-CMOS batch fabrication is also feasible (Ikuta et al. 1996; Zissi

1996).

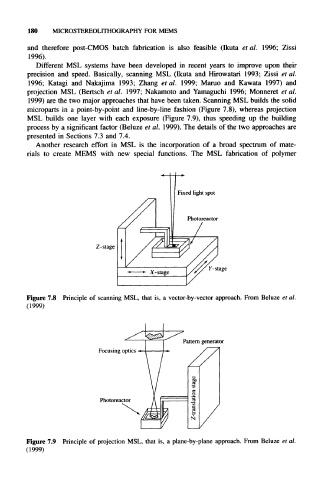

Different MSL systems have been developed in recent years to improve upon their

precision and speed. Basically, scanning MSL (Ikuta and Hirowatari 1993; Zissi el al.

1996; Katagi and Nakajima 1993; Zhang et al. 1999; Maruo and Kawata 1997) and

projection MSL (Bertsch et al. 1997; Nakamoto and Yamaguchi 1996; Monneret et al.

1999) are the two major approaches that have been taken. Scanning MSL builds the solid

microparts in a point-by-point and line-by-line fashion (Figure 7.8), whereas projection

MSL builds one layer with each exposure (Figure 7.9), thus speeding up the building

process by a significant factor (Beluze et al. 1999). The details of the two approaches are

presented in Sections 7.3 and 7.4.

Another research effort in MSL is the incorporation of a broad spectrum of mate-

rials to create MEMS with new special functions. The MSL fabrication of polymer

Z-stage

Y- stage

Figure 7.8 Principle of scanning MSL, that is, a vector-by-vector approach. From Beluze et al.

(1999)

Focusing optics -*

Photoreactor

Figure 7.9 Principle of projection MSL, that is, a plane-by-plane approach. From Beluze et al.

(1999)