Page 201 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 201

SCANNING METHOD 181

microparts and their subsequent electroplating to form metallic microparts have been

reported (Ikuta and Hirowatari 1993; Ikuta et al. 1996; Zissi et al. 1996; Katagi and Naka-

jima 1993; Maruo and Kawata 1997; Bertsch et al. 1997; Nakamoto and Yamaguchi 1996;

Monneret et al. 1999). Functional polymer (e.g. conducting polymer) microparts possess

the unusual characteristics of high flexibility, low density, and high electric conductivity

(Ikuta and Hirowatari 1993). Ceramic microstructures have also been fabricated by MSL

using both structural and functional ceramic materials (Zhang et al. 1999; Jiang et al.

1999). The use of MSL to make both ceramic and metallic microparts is discussed in

Section 7.7.

7.3 SCANNING METHOD

Most MSL equipment developed today are based on the scanning method (Figure 7.8),

which is the method employed in conventional SL and is widely used in the industry. With

the scanning method, a well-focussed laser beam with beam spot size around 1 micron is

directed onto the resin surface to initiate the polymerisation process. A 3-D microstructure

is built up by the repeated scanning of either the light beam or the work piece layer by

layer.

7.3.1 Classical MSL

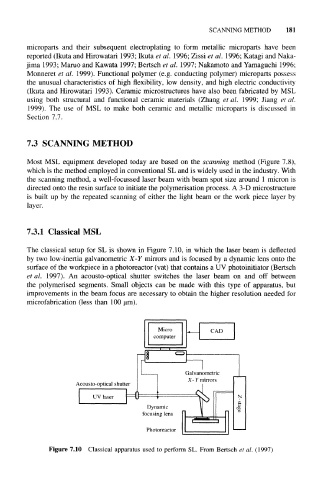

The classical setup for SL is shown in Figure 7.10, in which the laser beam is deflected

by two low-inertia galvanometric X-Y mirrors and is focused by a dynamic lens onto the

surface of the workpiece in a photoreactor (vat) that contains a UV photoinitiator (Bertsch

et al. 1997). An acousto-optical shutter switches the laser beam on and off between

the polymerised segments. Small objects can be made with this type of apparatus, but

improvements in the beam focus are necessary to obtain the higher resolution needed for

rnicrofabrication (less than 100 um).

Galvanometric

X-Y mirrors

Acousto-optical shutter

Dynamic

focusing lens

Photoreactor

Figure 7.10 Classical apparatus used to perform SL. From Bertsch et al. (1997)