Page 204 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 204

184 MICROSTEREOLITHOGRAPHY FOR MEMS

UVbeam

(b)

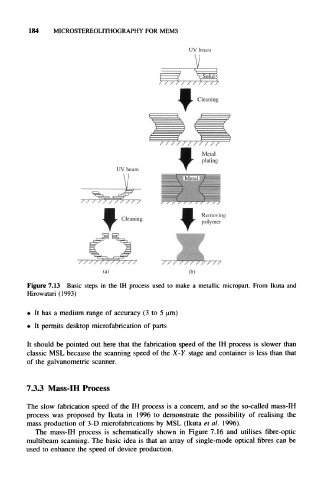

Figure 7.13 Basic steps in the IH process used to make a metallic micropart. From Ikuta and

Hirowatari (1993)

• It has a medium range of accuracy (3 to 5 urn)

• It permits desktop microfabrication of parts

It should be pointed out here that the fabrication speed of the IH process is slower than

classic MSL because the scanning speed of the X-Y stage and container is less than that

of the galvanometric scanner.

7.3.3 Mass-IH Process

The slow fabrication speed of the IH process is a concern, and so the so-called mass-IH

process was proposed by Ikuta in 1996 to demonstrate the possibility of realising the

mass production of 3-D microfabrications by MSL (Ikuta et al. 1996).

The mass-IH process is schematically shown in Figure 7.16 and utilises fibre-optic

multibeam scanning. The basic idea is that an array of single-mode optical fibres can be

used to enhance the speed of device production.