Page 206 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 206

186 MICROSTEREOLITHOGRAPHY FOR MEMS

UV light

Optical fibres

_l

i -»•

Stage I 1

r r r - 1

/A r^n r^A • • • £=\ A^

UV polymer i

Figure 7.16 The mass-IH process designed to increase the speed of MSL through the use of an

array of optical fibres. From Ikuta el al. (1996)

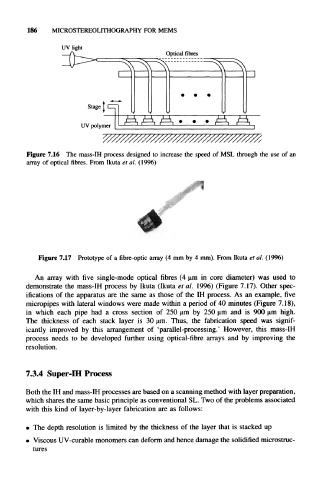

Figure 7.17 Prototype of a fibre-optic array (4 mm by 4 mm). From Ikuta et al. (19%)

An array with five single-mode optical fibres (4 um in core diameter) was used to

demonstrate the mass-IH process by Ikuta (Ikuta et al. 1996) (Figure 7.17). Other spec-

ifications of the apparatus are the same as those of the IH process. As an example, five

micropipes with lateral windows were made within a period of 40 minutes (Figure 7.18),

in which each pipe had a cross section of 250 u,m by 250 urn and is 900 u.m high.

The thickness of each stack layer is 30 um. Thus, the fabrication speed was signif-

icantly improved by this arrangement of 'parallel-processing.' However, this mass-IH

process needs to be developed further using optical-fibre arrays and by improving the

resolution.

7.3.4 Super-IH Process

Both the IH and mass-IH processes are based on a scanning method with layer preparation,

which shares the same basic principle as conventional SL. Two of the problems associated

with this kind of layer-by-layer fabrication are as follows:

• The depth resolution is limited by the thickness of the layer that is stacked up

• Viscous UV-curable monomers can deform and hence damage the solidified microstruc-

tures