Page 203 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 203

SCANNING METHOD 183

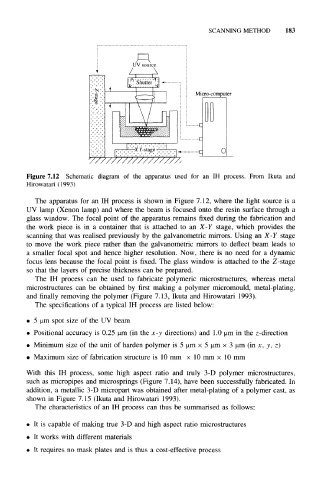

Figure 7.12 Schematic diagram of the apparatus used for an IH process. From Ikuta and

Hirowatari (1993)

The apparatus for an IH process is shown in Figure 7.12, where the light source is a

UV lamp (Xenon lamp) and where the beam is focused onto the resin surface through a

glass window. The focal point of the apparatus remains fixed during the fabrication and

the work piece is in a container that is attached to an X-Y stage, which provides the

scanning that was realised previously by the galvanometric mirrors. Using an X-Y stage

to move the work piece rather than the galvanometric mirrors to deflect beam leads to

a smaller focal spot and hence higher resolution. Now, there is no need for a dynamic

focus lens because the focal point is fixed. The glass window is attached to the Z-stage

so that the layers of precise thickness can be prepared.

The IH process can be used to fabricate polymeric microstructures, whereas metal

microstructures can be obtained by first making a polymer micromould, metal-plating,

and finally removing the polymer (Figure 7.13, Ikuta and Hirowatari 1993).

The specifications of a typical IH process are listed below:

• 5 um spot size of the UV beam

• Positional accuracy is 0.25 urn (in the x-y directions) and 1.0 um in the z-direction

• Minimum size of the unit of harden polymer is 5 um x 5 um x 3 urn (in x, y, z)

• Maximum size of fabrication structure is 10 mm x 10 mm x 10 mm

With this IH process, some high aspect ratio and truly 3-D polymer microstructures,

such as micropipes and microsprings (Figure 7.14), have been successfully fabricated. In

addition, a metallic 3-D micropart was obtained after metal-plating of a polymer cast, as

shown in Figure 7.15 (Ikuta and Hirowatari 1993).

The characteristics of an IH process can thus be summarised as follows:

• It is capable of making true 3-D and high aspect ratio microstructures

• It works with different materials

• It requires no mask plates and is thus a cost-effective process