Page 208 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 208

188 MICROSTEREOLITHOGRAPHY FOR MEMS

UV polymer

X-Y-Z stage

Shutter

ND filter

Figure 7.20 Experimental setup of the super-IH process

I Stage down

Laser beam Beam scanning

(a) (b)

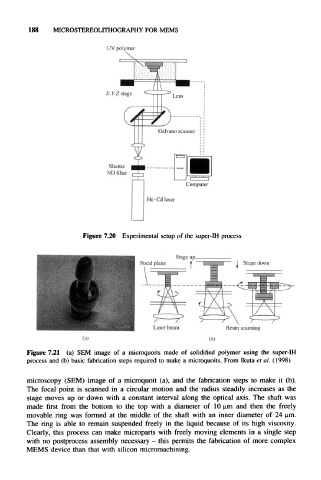

Figure 7.21 (a) SEM image of a microquoits made of solidified polymer using the super-IH

process and (b) basic fabrication steps required to make a microquoits. From Ikuta et al. (1998)

microscopy (SEM) image of a microquoit (a), and the fabrication steps to make it (b).

The focal point is scanned in a circular motion and the radius steadily increases as the

stage moves up or down with a constant interval along the optical axis. The shaft was

made first from the bottom to the top with a diameter of 10 urn and then the freely

movable ring was formed at the middle of the shaft with an inner diameter of 24 urn.

The ring is able to remain suspended freely in the liquid because of its high viscosity.

Clearly, this process can make microparts with freely moving elements in a single step

with no postprocess assembly necessary - this permits the fabrication of more complex

MEMS device than that with silicon micromachining.