Page 212 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 212

192 MICROSTEREOLITHOGRAPHY FOR MEMS

and depth resolution obtained with two-photon MSL were 0.62 and 2.2 um, respectively.

It is important to note that a depth resolution of only 2.2 um is difficult to achieve with

conventional MSL. However, the longest total length of a structure in the direction of the

optical axis was up to 74.3 um, which is a limitation of two-photon MSL. In addition,

the two-photon MSL system is more expensive than most of the other types of MSL

equipment.

7.5 OTHER MSL APPROACHES

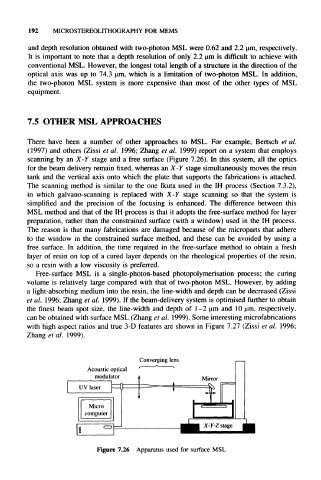

There have been a number of other approaches to MSL. For example, Bertsch et al.

(1997) and others (Zissi et al. 1996; Zhang et al. 1999) report on a system that employs

scanning by an X-Y stage and a free surface (Figure 7.26). In this system, all the optics

for the beam delivery remain fixed, whereas an X-Y stage simultaneously moves the resin

tank and the vertical axis onto which the plate that supports the fabrications is attached.

The scanning method is similar to the one Ikuta used in the IH process (Section 7.3.2),

in which galvano-scanning is replaced with X-Y stage scanning so that the system is

simplified and the precision of the focusing is enhanced. The difference between this

MSL method and that of the IH process is that it adopts the free-surface method for layer

preparation, rather than the constrained surface (with a window) used in the IH process.

The reason is that many fabrications are damaged because of the microparts that adhere

to the window in the constrained surface method, and these can be avoided by using a

free surface. In addition, the time required in the free-surface method to obtain a fresh

layer of resin on top of a cured layer depends on the rheological properties of the resin,

so a resin with a low viscosity is preferred.

Free-surface MSL is a single-photon-based photopolymerisation process; the curing

volume is relatively large compared with that of two-photon MSL. However, by adding

a light-absorbing medium into the resin, the line-width and depth can be decreased (Zissi

et al. 1996; Zhang et al. 1999). If the beam-delivery system is optimised further to obtain

the finest beam spot size, the line-width and depth of 1-2 um and 10 um, respectively,

can be obtained with surface MSL (Zhang et al. 1999). Some interesting microfabrications

with high aspect ratios and true 3-D features are shown in Figure 7.27 (Zissi et al. 1996;

Zhang et al. 1999).

Converging lens

Acoustic optical

modulator

Figure 7.26 Apparatus used for surface MSL