Page 217 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 217

POLYMERIC MEMS ARCHITECTURE 197

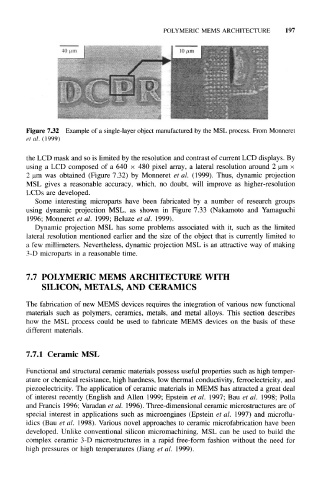

Figure 7.32 Example of a single-layer object manufactured by the MSL process. From Monneret

et al. (1999)

the LCD mask and so is limited by the resolution and contrast of current LCD displays. By

using a LCD composed of a 640 x 480 pixel array, a lateral resolution around 2 um x

2 um was obtained (Figure 7.32) by Monneret et al. (1999). Thus, dynamic projection

MSL gives a reasonable accuracy, which, no doubt, will improve as higher-resolution

LCDs are developed.

Some interesting microparts have been fabricated by a number of research groups

using dynamic projection MSL, as shown in Figure 7.33 (Nakamoto and Yamaguchi

1996; Monneret et al. 1999; Beluze et al. 1999).

Dynamic projection MSL has some problems associated with it, such as the limited

lateral resolution mentioned earlier and the size of the object that is currently limited to

a few millimeters. Nevertheless, dynamic projection MSL is an attractive way of making

3-D microparts in a reasonable time.

7.7 POLYMERIC MEMS ARCHITECTURE WITH

SILICON, METALS, AND CERAMICS

The fabrication of new MEMS devices requires the integration of various new functional

materials such as polymers, ceramics, metals, and metal alloys. This section describes

how the MSL process could be used to fabricate MEMS devices on the basis of these

different materials.

7.7.1 Ceramic MSL

Functional and structural ceramic materials possess useful properties such as high temper-

ature or chemical resistance, high hardness, low thermal conductivity, ferroelectricity, and

piezoelectricity. The application of ceramic materials in MEMS has attracted a great deal

of interest recently (English and Allen 1999; Epstein et al. 1997; Bau et al. 1998; Polla

and Francis 1996; Varadan et al. 1996). Three-dimensional ceramic microstructures are of

special interest in applications such as microengines (Epstein et al. 1997) and microflu-

idics (Bau et al. 1998). Various novel approaches to ceramic microfabrication have been

developed. Unlike conventional silicon micromachining, MSL can be used to build the

complex ceramic 3-D microstructures in a rapid free-form fashion without the need for

high pressures or high temperatures (Jiang et al. 1999).