Page 216 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 216

196 MICROSTEREOLITHOGRAPHY FOR MEMS

7.6.2 Dynamic Mask-Projection MSL

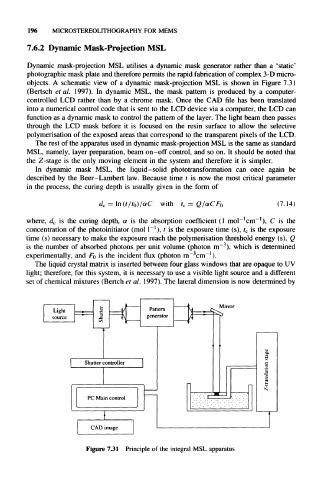

Dynamic mask-projection MSL utilises a dynamic mask generator rather than a 'static'

photographic mask plate and therefore permits the rapid fabrication of complex 3-D micro-

objects. A schematic view of a dynamic mask-projection MSL is shown in Figure 7.31

(Bertsch et al. 1997). In dynamic MSL, the mask pattern is produced by a computer-

controlled LCD rather than by a chrome mask. Once the CAD file has been translated

into a numerical control code that is sent to the LCD device via a computer, the LCD can

function as a dynamic mask to control the pattern of the layer. The light beam then passes

through the LCD mask before it is focused on the resin surface to allow the selective

polymerisation of the exposed areas that correspond to the transparent pixels of the LCD.

The rest of the apparatus used in dynamic mask-projection MSL is the same as standard

MSL, namely, layer preparation, beam on-off control, and so on. It should be noted that

the Z-stage is the only moving element in the system and therefore it is simpler.

In dynamic mask MSL, the liquid-solid phototransformation can once again be

described by the Beer-Lambert law. Because time t is now the most critical parameter

in the process, the curing depth is usually given in the form of

= In(t/t 0 )/aC with t c = (7.14)

d c Q/aCF 0

–1 – 1

where, d c is the curing depth, a is the absorption coefficient (1 mol cm ), C is the

– 1

t

concentration of the photoinitiator (mol I ), t is the exposure time (s), c is the exposure

time (s) necessary to make the exposure reach the polymerisation threshold energy (s), Q

– 3

is the number of absorbed photons per unit volume (photon m ), which is determined

–1

–3

experimentally, and F 0 is the incident flux (photon m cm ).

The liquid crystal matrix is inserted between four glass windows that are opaque to UV

light; therefore, for this system, it is necessary to use a visible light source and a different

set of chemical mixtures (Bertch et al. 1997). The lateral dimension is now determined by

Shutter controller

PC Main control

CAD image

Figure 7.31 Principle of the integral MSL apparatus