Page 384 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 384

364 IDT MICROSENSORS

w

i t

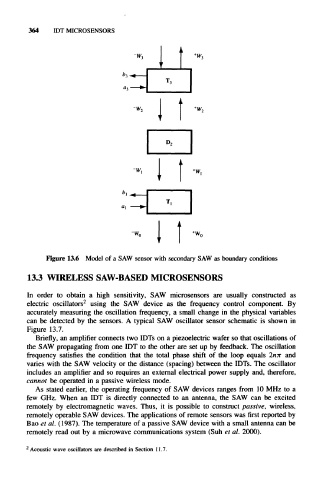

Figure 13.6 Model of a SAW sensor with secondary SAW as boundary conditions

13.3 WIRELESS SAW-BASED MICROSENSORS

In order to obtain a high sensitivity, SAW microsensors are usually constructed as

electric oscillators 2 using the SAW device as the frequency control component. By

accurately measuring the oscillation frequency, a small change in the physical variables

can be detected by the sensors. A typical SAW oscillator sensor schematic is shown in

Figure 13.7.

Briefly, an amplifier connects two DDTs on a piezoelectric wafer so that oscillations of

the SAW propagating from one IDT to the other are set up by feedback. The oscillation

frequency satisfies the condition that the total phase shift of the loop equals 2n and

varies with the SAW velocity or the distance (spacing) between the IDTs. The oscillator

includes an amplifier and so requires an external electrical power supply and, therefore,

cannot be operated in a passive wireless mode.

As stated earlier, the operating frequency of SAW devices ranges from 10 MHz to a

few GHz. When an IDT is directly connected to an antenna, the SAW can be excited

remotely by electromagnetic waves. Thus, it is possible to construct passive, wireless,

remotely operable SAW devices. The applications of remote sensors was first reported by

Bao et al. (1987). The temperature of a passive SAW device with a small antenna can be

remotely read out by a microwave communications system (Suh et al. 2000).

2

Acoustic wave oscillators are described in Section 11.7.