Page 95 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 95

76 STANDARD MICROELECTRONIC TECHNOLOGIES

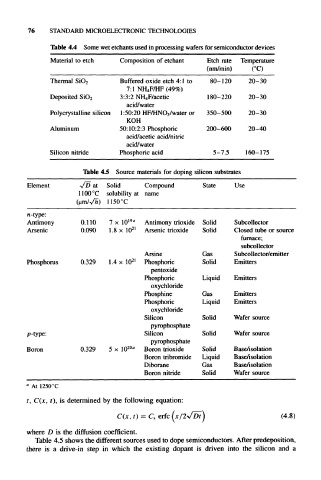

Table 4.4 Some wet etchants used in processing wafers for semiconductor devices

Material to etch Composition of etchant Etch rate Temperature

(nm/min) (°C)

Thermal SiO2 Buffered oxide etch 4: 1 to 80-120 20-30

7:1 NH4F/HF(49%)

Deposited SiO2 3:3:2 NF 4F/acetic 180-220 20-30

acid/water

Polycrystalline silicon 1:50:20 HF/HNO 3/water or 350-500 20-30

KOH

Aluminum 50:10:2:3 Phosphoric 200-600 20-40

acid/acetic acid/nitric

acid/water

Silicon nitride Phosphoric acid 5-7.5 160-175

Table 4.5 Source materials for doping silicon substrates

Element \/D at Solid Compound State Use

1100°C solubility at name

(um 1150°C

n-type:

Antimony 0.110 7xl0 1 9 a Antimony trioxide Solid Subcollector

Arsenic 0.090 1.8 x 10 21 Arsenic trioxide Solid Closed tube or source

furnace;

subcollector

Arsine Gas Subcollector/emitter

Phosphorus 0.329 1.4X10 21 Phosphoric Solid Emitters

pentoxide

Phosphoric Liquid Emitters

oxychloride

Phosphine Gas Emitters

Phosphoric Liquid Emitters

oxychloride

Silicon Solid Wafer source

pyrophosphate

p-type: Silicon Solid Wafer source

pyrophosphate

Boron 0.329 5 x lO 20a Boron trioxide Solid Base/isolation

Boron tribromide Liquid Base/isolation

Diborane Gas Base/isolation

Boron nitride Solid Wafer source

a

At 1250°C

t, C(x, t), is determined by the following equation:

C(x, t) = C s erfc (4.8)

where D is the diffusion coefficient.

Table 4.5 shows the different sources used to dope semiconductors. After predeposition,

there is a drive-in step in which the existing dopant is driven into the silicon and a