Page 277 - Modular design for machine tools

P. 277

236 Engineering Design for Machine Tool Joints

N

P P

380

P

f250

P

(a)

S = 225 cm 2

P

(b)

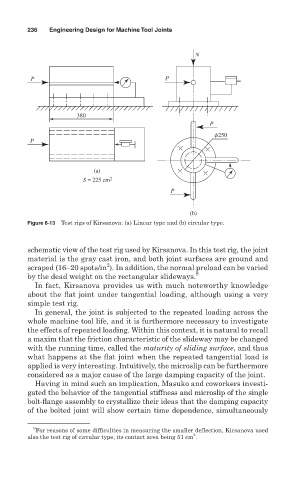

Figure 6-13 Test rigs of Kirsanova: (a) Linear type and (b) circular type.

schematic view of the test rig used by Kirsanova. In this test rig, the joint

material is the gray cast iron, and both joint surfaces are ground and

2

scraped (16–20 spots/in ). In addition, the normal preload can be varied

by the dead weight on the rectangular slideways. 9

In fact, Kirsanova provides us with much noteworthy knowledge

about the flat joint under tangential loading, although using a very

simple test rig.

In general, the joint is subjected to the repeated loading across the

whole machine tool life, and it is furthermore necessary to investigate

the effects of repeated loading. Within this context, it is natural to recall

a maxim that the friction characteristic of the slideway may be changed

with the running time, called the maturity of sliding surface, and thus

what happens at the flat joint when the repeated tangential load is

applied is very interesting. Intuitively, the microslip can be furthermore

considered as a major cause of the large damping capacity of the joint.

Having in mind such an implication, Masuko and coworkers investi-

gated the behavior of the tangential stiffness and microslip of the single

bolt-flange assembly to crystallize their ideas that the damping capacity

of the bolted joint will show certain time dependence, simultaneously

9

For reasons of some difficulties in measuring the smaller deflection, Kirsanova used

2

also the test rig of circular type, its contact area being 51 cm .