Page 279 - Modular design for machine tools

P. 279

238 Engineering Design for Machine Tool Joints

the second loading cycle and beyond, i.e., progressive loop type.

Importantly, Masuko and his coworkers suggested that the hysteresis

loop is caused by the microslip at the contact asperities under the elas-

tic and plastic deformation. As a result, damping at the single bolted

joint can be characterized by its viscous—and dry frictionlike property

(see Chap. 7).

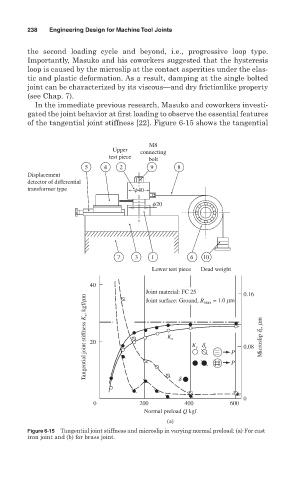

In the immediate previous research, Masuko and coworkers investi-

gated the joint behavior at first loading to observe the essential features

of the tangential joint stiffness [22]. Figure 6-15 shows the tangential

M8

Upper connecting

test piece

bolt

5 4 2 9 8

Displacement

detector of differential

transformer type f40

f20

7 3 1 6 10

Lower test piece Dead weight

40

Joint material: FC 25 = 1.0 mm 0.16

Tangential joint stiffness K s , kgf/mm 20 K s K d r P 0.08 mm Microslip d r ,

Joint surface: Ground, R max

s

P

d

0

0 200 400 600

Normal preload Q kgf

(a)

Figure 6-15 Tangential joint stiffness and microslip in varying normal preload: (a) For cast

iron joint and (b) for brass joint.