Page 293 - Modular design for machine tools

P. 293

252 Engineering Design for Machine Tool Joints

Expressions

(Groth, 1972 [39])

(Tsutsumi & Ito,

(Reshetov &

Levina, 1956 [38]) (Dekoninck, 1972 [40]) 1980 [41])

1960 1970 1980 1990 2000

(Rogers & Boothroyd, (Beards &

1975 [25]) Neroutsopoulos,

Hysteresis loop 1980 [43])

Loss factor of

EDM joint

(Hashimoto &

Kume, 1972 [42]) Hysteresis loop, vibration

Vibration transmittability transmittability, loss

factor and so on

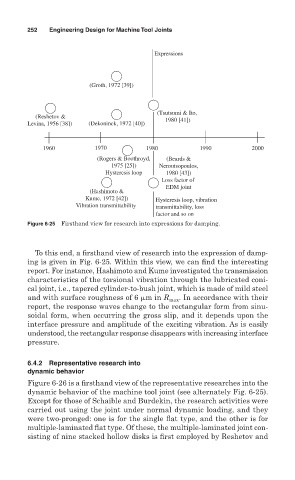

Figure 6-25 Firsthand view for research into expressions for damping.

To this end, a firsthand view of research into the expression of damp-

ing is given in Fig. 6-25. Within this view, we can find the interesting

report. For instance, Hashimoto and Kume investigated the transmission

characteristics of the torsional vibration through the lubricated coni-

cal joint, i.e., tapered cylinder- to-bush joint, which is made of mild steel

and with surface roughness of 6 m in R max . In accordance with their

report, the response waves change to the rectangular form from sinu-

soidal form, when occurring the gross slip, and it depends upon the

interface pressure and amplitude of the exciting vibration. As is easily

understood, the rectangular response disappears with increasing interface

pressure.

6.4.2 Representative research into

dynamic behavior

Figure 6-26 is a firsthand view of the representative researches into the

dynamic behavior of the machine tool joint (see alternately Fig. 6-25).

Except for those of Schaible and Burdekin, the research activities were

carried out using the joint under normal dynamic loading, and they

were two-pronged: one is for the single flat type, and the other is for

multiple-laminated flat type. Of these, the multiple-laminated joint con-

sisting of nine stacked hollow disks is first employed by Reshetov and