Page 294 - Modular design for machine tools

P. 294

Engineering Design Fundamentals and Single Flat Joint Characteristics 253

Multiple-laminated

joint

(Andrew et al.,

1967 [46])

(Loewenfeld,

1959 [44])

(Burdekin et al.,

(Reshetov & (PERA, late

Levina, 1956 [38]) 1960s [45]) 1978 [27])

Tangential loading

1960 1970 1980 1990 2000

(Schaible, 1974 [47])

(Eisele & Corbach,

Column-to-base joint,

1964 [9]) bending excitation

(Corbach, (Thornley & (Schaible,

1966 [14]) Koenigsberger, 1977 [48])

1971 [49])

Single joint

(Thornley &

Lees, 1971 [50])

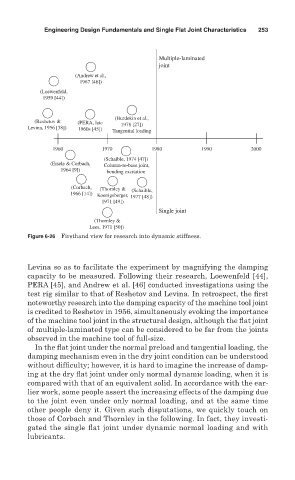

Figure 6-26 Firsthand view for research into dynamic stiffness.

Levina so as to facilitate the experiment by magnifying the damping

capacity to be measured. Following their research, Loewenfeld [44],

PERA [45], and Andrew et al. [46] conducted investigations using the

test rig similar to that of Reshetov and Levina. In retrospect, the first

noteworthy research into the damping capacity of the machine tool joint

is credited to Reshetov in 1956, simultaneously evoking the importance

of the machine tool joint in the structural design, although the flat joint

of multiple-laminated type can be considered to be far from the joints

observed in the machine tool of full-size.

In the flat joint under the normal preload and tangential loading, the

damping mechanism even in the dry joint condition can be understood

without difficulty; however, it is hard to imagine the increase of damp-

ing at the dry flat joint under only normal dynamic loading, when it is

compared with that of an equivalent solid. In accordance with the ear-

lier work, some people assert the increasing effects of the damping due

to the joint even under only normal loading, and at the same time

other people deny it. Given such disputations, we quickly touch on

those of Corbach and Thornley in the following. In fact, they investi-

gated the single flat joint under dynamic normal loading and with

lubricants.