Page 295 - Modular design for machine tools

P. 295

254 Engineering Design for Machine Tool Joints

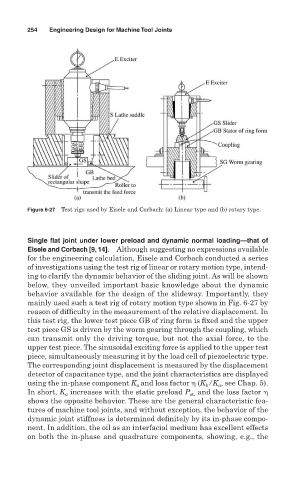

Figure 6-27 Test rigs used by Eisele and Corbach: (a) Linear type and (b) rotary type.

Single flat joint under lower preload and dynamic normal loading—that of

Eisele and Corbach [9, 14]. Although suggesting no expressions available

for the engineering calculation, Eisele and Corbach conducted a series

of investigations using the test rig of linear or rotary motion type, intend-

ing to clarify the dynamic behavior of the sliding joint. As will be shown

below, they unveiled important basic knowledge about the dynamic

behavior available for the design of the slideway. Importantly, they

mainly used such a test rig of rotary motion type shown in Fig. 6-27 by

reason of difficulty in the measurement of the relative displacement. In

this test rig, the lower test piece GB of ring form is fixed and the upper

test piece GS is driven by the worm gearing through the coupling, which

can transmit only the driving torque, but not the axial force, to the

upper test piece. The sinusoidal exciting force is applied to the upper test

piece, simultaneously measuring it by the load cell of piezoelectric type.

The corresponding joint displacement is measured by the displacement

detector of capacitance type, and the joint characteristics are displayed

using the in-phase component K and loss factor (K /K , see Chap. 5).

a

b

a

In short, K increases with the static preload P st, and the loss factor

a

shows the opposite behavior. These are the general characteristic fea-

tures of machine tool joints, and without exception, the behavior of the

dynamic joint stiffness is determined definitely by its in-phase compo-

nent. In addition, the oil as an interfacial medium has excellent effects

on both the in-phase and quadrature components, showing, e.g., the