Page 291 - Modular design for machine tools

P. 291

250 Engineering Design for Machine Tool Joints

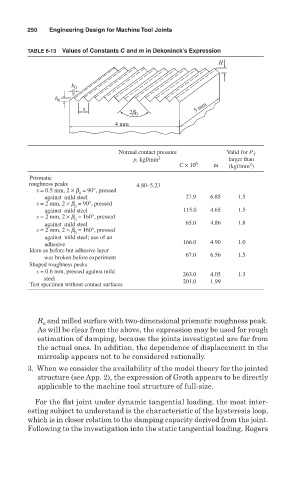

TABLE 6-13 Values of Constants C and m in Dekoninck’s Expression

H

b 0

h 0

s 5 mm

2b 0

4 mm

Normal contact pressure Valid for P t

p, kgf/mm 2 larger than

2

C × 10 6 m (kgf/mm )

Prismatic

roughness peaks 4.80–5.23

s = 0.5 mm, 2 × b = 90°, pressed

0

against mild steel 27.9 6.85 1.5

s = 2 mm, 2 × b = 90°, pressed

0

against mild steel 115.0 4.65 1.5

s = 2 mm, 2 × b = 160°, pressed

0

against mild steel 65.0 4.86 1.8

s = 2 mm, 2 × b = 160°, pressed

0

against mild steel; use of an

166.0 4.90 1.0

adhesive

Idem as before but adhesive layer

67.0 6.56 1.5

was broken before experiment

Shaped roughness peaks

s = 0.6 mm, pressed against mild

263.0 4.05 1.3

steel

Test specimen without contact surfaces 201.0 1.99

R and milled surface with two-dimensional prismatic roughness peak.

a

As will be clear from the above, the expression may be used for rough

estimation of damping, because the joints investigated are far from

the actual ones. In addition, the dependence of displacement in the

microslip appears not to be considered rationally.

3. When we consider the availability of the model theory for the jointed

structure (see App. 2), the expression of Groth appears to be directly

applicable to the machine tool structure of full-size.

For the flat joint under dynamic tangential loading, the most inter-

esting subject to understand is the characteristic of the hysteresis loop,

which is in closer relation to the damping capacity derived from the joint.

Following to the investigation into the static tangential loading, Rogers