Page 288 - Modular design for machine tools

P. 288

Engineering Design Fundamentals and Single Flat Joint Characteristics 247

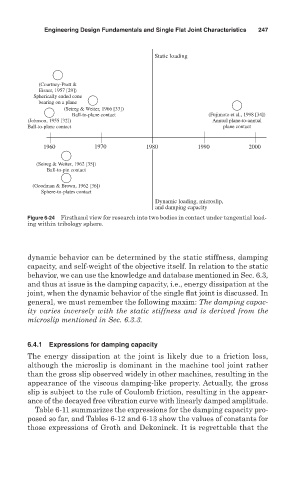

Static loading

(Courtney-Pratt &

Eisner, 1957 [29])

Spherically ended cone

bearing on a plane

(Seireg & Weiter, 1966 [33])

Ball-to-plane contact (Fujimoto et al., 1998 [34])

(Johnson, 1955 [32]) Annual plane-to-annual

Ball-to-plane contact plane contact

1960 1970 1980 1990 2000

(Seireg & Weiter, 1962 [35])

Ball-to-pin contact

(Goodman & Brown, 1962 [36])

Sphere-to-plates contact

Dynamic loading, microslip,

and damping capacity

Figure 6-24 Firsthand view for research into two bodies in contact under tangential load-

ing within tribology sphere.

dynamic behavior can be determined by the static stiffness, damping

capacity, and self-weight of the objective itself. In relation to the static

behavior, we can use the knowledge and database mentioned in Sec. 6.3,

and thus at issue is the damping capacity, i.e., energy dissipation at the

joint, when the dynamic behavior of the single flat joint is discussed. In

general, we must remember the following maxim: The damping capac-

ity varies inversely with the static stiffness and is derived from the

microslip mentioned in Sec. 6.3.3.

6.4.1 Expressions for damping capacity

The energy dissipation at the joint is likely due to a friction loss,

although the microslip is dominant in the machine tool joint rather

than the gross slip observed widely in other machines, resulting in the

appearance of the viscous damping-like property. Actually, the gross

slip is subject to the rule of Coulomb friction, resulting in the appear-

ance of the decayed free vibration curve with linearly damped amplitude.

Table 6-11 summarizes the expressions for the damping capacity pro-

posed so far, and Tables 6-12 and 6-13 show the values of constants for

those expressions of Groth and Dekoninck. It is regrettable that the