Page 455 - Book Hosokawa Nanoparticle Technology Handbook

P. 455

2 GENERATION OF METAL NANOPARTICLES APPLICATIONS

Table 2.1

The example of manufacturing nanoparticles.

Material Atmosphere Obtained

gas kind particles

Pure metal Hydrogen Fe, Cu, Ni, Co,

Cr, Ti, In, ...

Alloy Hydrogen Fe–Ni, Fe–Co,

Ag–Cu, Ag–Pd, ...

Metal or nitride Nitrogen TiN, ZrN,

AlN, AlN Al, ...

Metal or carbide Hydrogen SiC, TiC, ...

Boronide Hydrogen LaB 6

Metal or oxide Oxygen WO , MoO ,

3

3

Nb O , ...

2

5

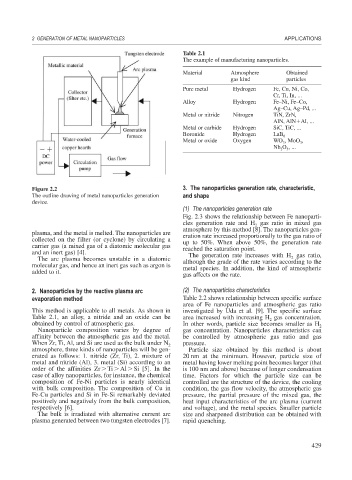

Figure 2.2 3. The nanoparticles generation rate, characteristic,

The outline drawing of metal nanoparticles generation and shape

device.

(1) The nanoparticles generation rate

Fig. 2.3 shows the relationship between Fe nanoparti-

cles generation rate and H gas ratio in mixed gas

2

atmosphere by this method [8]. The nanoparticles gen-

plasma, and the metal is melted. The nanoparticles are eration rate increased proportionally to the gas ratio of

collected on the filter (or cyclone) by circulating a up to 50%. When above 50%, the generation rate

carrier gas (a mixed gas of a diatomic molecular gas reached the saturation point.

and an inert gas) [4]. The generation rate increases with H gas ratio,

2

The arc plasma becomes unstable in a diatomic although the grade of the rate varies according to the

molecular gas, and hence an inert gas such as argon is metal species. In addition, the kind of atmospheric

added to it.

gas affects on the rate.

2. Nanoparticles by the reactive plasma arc (2) The nanoparticles characteristics

evaporation method Table 2.2 shows relationship between specific surface

area of Fe nanoparticles and atmospheric gas ratio

This method is applicable to all metals. As shown in investigated by Uda et al. [9]. The specific surface

Table 2.1, an alloy, a nitride and an oxide can be area increased with increasing H gas concentration.

2

obtained by control of atmospheric gas. In other words, particle size becomes smaller as H 2

Nanoparticle composition varies by degree of gas concentration. Nanoparticles characteristics can

affinity between the atmospheric gas and the metal. be controlled by atmospheric gas ratio and gas

When Zr, Ti, Al, and Si are used as the bulk under N 2 pressure.

atmosphere, three kinds of nanoparticles will be gen- Particle size obtained by this method is about

erated as follows: 1. nitride (Zr, Ti), 2. mixture of 20 nm at the minimum. However, particle size of

metal and nitride (Al), 3. metal (Si) according to an metal having lower melting point becomes larger (that

order of the affinities Zr Ti Al Si [5]. In the is 100 nm and above) because of longer condensation

case of alloy nanoparticles, for instance, the chemical time. Factors for which the particle size can be

composition of Fe-Ni particles is nearly identical controlled are the structure of the device, the cooling

with bulk composition. The composition of Cu in condition, the gas flow velocity, the atmospheric gas

Fe-Cu particles and Si in Fe-Si remarkably deviated pressure, the partial pressure of the mixed gas, the

positively and negatively from the bulk composition, heat input characteristics of the arc plasma (current

respectively [6]. and voltage), and the metal species. Smaller particle

The bulk is irradiated with alternative current arc size and sharpened distribution can be obtained with

plasma generated between two tungsten electrodes [7]. rapid quenching.

429