Page 570 - Book Hosokawa Nanoparticle Technology Handbook

P. 570

APPLICATIONS 28 DEVELOPMENT OF FUEL CELLS

(a) (b)

500nm Ni

(c)

O

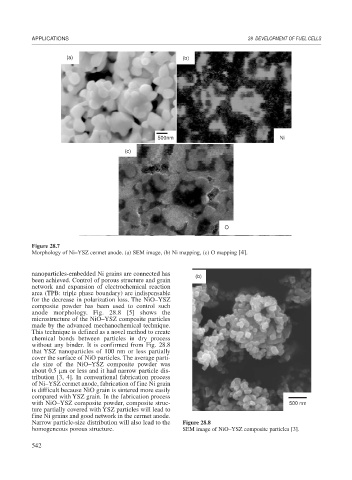

Figure 28.7

Morphology of Ni–YSZ cermet anode. (a) SEM image, (b) Ni mapping, (c) O mapping [4].

nanoparticles-embedded Ni grains are connected has (b)

been achieved. Control of porous structure and grain

network and expansion of electrochemical reaction

area (TPB: triple phase boundary) are indispensable

for the decrease in polarization loss. The NiO–YSZ

composite powder has been used to control such

anode morphology. Fig. 28.8 [5] shows the

microstructure of the NiO–YSZ composite particles

made by the advanced mechanochemical technique.

This technique is defined as a novel method to create

chemical bonds between particles in dry process

without any binder. It is confirmed from Fig. 28.8

that YSZ nanoparticles of 100 nm or less partially

cover the surface of NiO particles. The average parti-

cle size of the NiO–YSZ composite powder was

about 0.5 m or less and it had narrow particle dis-

tribution [3, 4]. In conventional fabrication process

of Ni–YSZ cermet anode, fabrication of fine Ni grain

is difficult because NiO grain is sintered more easily

compared with YSZ grain. In the fabrication process

with NiO–YSZ composite powder, composite struc- 500 nm

ture partially covered with YSZ particles will lead to

fine Ni grains and good network in the cermet anode.

Narrow particle-size distribution will also lead to the Figure 28.8

homogeneous porous structure. SEM image of NiO–YSZ composite particles [3].

542