Page 569 - Book Hosokawa Nanoparticle Technology Handbook

P. 569

28 DEVELOPMENT OF FUEL CELLS APPLICATIONS

electrolyte of 10 m in thickness has been obtained in The decrease of polarization loss was also suc-

the developed cell. This thin-film electrolyte depends cessfully realized by microstructure control of the

on the cell structure, and the anode plays the role of the electrodes in addition to making of the thin-film

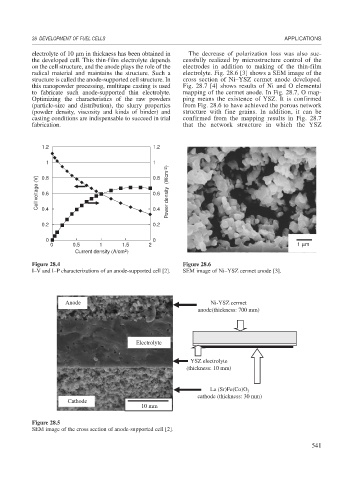

radical material and maintains the structure. Such a electrolyte. Fig. 28.6 [3] shows a SEM image of the

structure is called the anode-supported cell structure. In cross section of Ni–YSZ cermet anode developed.

this nanopowder processing, multitape casting is used Fig. 28.7 [4] shows results of Ni and O elemental

to fabricate such anode-supported thin electrolyte. mapping of the cermet anode. In Fig. 28.7, O map-

Optimizing the characteristics of the raw powders ping means the existence of YSZ. It is confirmed

(particle-size and distribution), the slurry properties from Fig. 28.6 to have achieved the porous network

(powder density, viscosity and kinds of binder) and structure with fine grains. In addition, it can be

casting conditions are indispensable to succeed in trial confirmed from the mapping results in Fig. 28.7

fabrication. that the network structure in which the YSZ

1.2 1.2

1 1

Cell voltage (V) 0.8 0.8 Power density (Wcm -2 )

0.6

0.6

0.4

0.2 0.4

0.2

0 0

0 0.5 1 1.5 2 1 μm

Current density (A/cm 2 )

Figure 28.4 Figure 28.6

I–V and I–P characterizations of an anode-supported cell [2]. SEM image of Ni–YSZ cermet anode [3].

Anode Ni-YSZ cermet

anode(thickness: 700 mm)

Electrolyte

YSZ electrolyte

(thickness: 10 mm)

La (Sr)Fe(Co)O 3

cathode (thickness: 30 mm)

Cathode

10 mm

Figure 28.5

SEM image of the cross section of anode-supported cell [2].

541