Page 450 - Offshore Electrical Engineering Manual

P. 450

Preparation and Use of Performance Standards 437

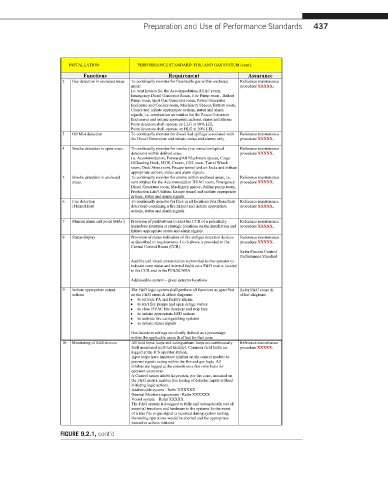

INSTALLATION: PERFORMANCE STANDARD: FIRE AND GAS SYSTEM (cont.)

Functions Requirement Assurance

2 Gas detection in enclosed areas. To continually monitor for flammable gas within enclosed Reference maintenance

areas: procedure XXXXX.

i.e. vent intakes for the Accommodation HVAC room,

Emergency Diesel Generator Room, Fire Pump room , Ballast

Pump room, Inert Gas Generator room, Power Generator

Enclosure and Coolers room, Machinery Spaces, Battery room,

Cranes and initiate appropriate actions, status and alarm

signals, i.e. combustion air intakes for the Power Generator

Enclosures and initiate appropriate actions, status and alarms

Point detectors shall operate on LLG at 10% LEL

Point detectors shall operate on HLG at 20% LEL

3 Oil Mist detection To continually monitor for diesel fuel spillage associated with Reference maintenance

the Diesel Generators and initiate status and alarms only. procedure XXXXX.

4 Smoke detection in open areas. To continually monitor for smoke (via ionisation/optical Reference maintenance

detectors) within defined areas: procedure XXXXX.

i.e. Accommodation, Forward/Aft Machinery spaces, Cargo

Offloading Deck, MCR, Cranes, CO2 room, Turret Winch

room, Deck Store room, Escape tunnel and air locks and initiate

appropriate actions, status and alarm signals.

5 Smoke detection in enclosed To continually monitor for smoke within enclosed areas, i.e. Reference maintenance

areas. vent intakes for the Accommodation HVAC room, Emergency procedure XXXXX.

Diesel Generator room, Machinery spaces, Ballast pump room,

Production Lab/Utilities, Escape tunnel and initiate appropriate

actions, status and alarm signals.

6 Fire detection To continually monitor for fires in all locations (via flame/heat Reference maintenance

(Flame/Heat) detection) containing a fire hazard and initiate appropriate procedure XXXXX.

actions, status and alarm signals.

7 Manualalarm call point (MAC) Provision of pushbuttons to alert the CCR of a potentially Reference maintenance

hazardous situation at strategic locations on the installation and procedure XXXXX.

initiate appropriate status and alarm signals.

8 Status display Provision of status indication of fire and gas detection devices Reference maintenance

as described in requirements 1 to 6 above is provided in the procedure XXXXX.

Central Control Room (CCR).

Refer Process Control

Performance Standard

Audible and visual annunciation is provided to the operator to

indicate zone status and internal faults on a F&G matrix located

in the CCR and in the PCS/SCADA.

Addressable system – gives detector locations

9 Initiate appropriate output The F&G logic system shall perform all functions as specified Refer F&G cause &

actions on the F&G cause & effect diagrams: effect diagrams

∑ to activate PA and facility alarms

∑ to start fire pumps and open deluge valves

∑ to close HVAC fire dampers and stop fans

∑ to initiate appropriate ESD actions

∑ to activate fire extinguishing systems

∑ to initiate status signals

Gas detection settings are clearly defined as a percentage

within the applicable cause & effect for that zone.

10 Monitoring of field devices All field input loops and extinguishant loops are continuously Reference maintenance

fault monitored (self-test facility). Common field faults are procedure XXXXX.

logged at the ICS operator station.

Input loops have hardware inhibits on the control module to

prevent signals acting within the fire and gas logic. All

inhibits are logged at the console on a fire zone basis for

operator awareness.

A Control action inhibit keyswitch, per fire zone, mounted on

the F&G matrix enables live testing of detector inputs without

initiating logic actions.

Addressable system -Refer XXXXXX

General Monitors equipment -Refer XXXXXX

Vesselsystem – Refer XXXXX

The F&G system is designed to fully and automatically test all

essential functions and hardware in the systems. In the event

of a true fire or gas signal is received during system testing,

the testing operations would be aborted and the appropriate

executive actions initiated.

FIGURE 9.2.1, cont’d