Page 451 - Offshore Electrical Engineering Manual

P. 451

438 CHAPTER 2 Preparation and Use of Performance Standards

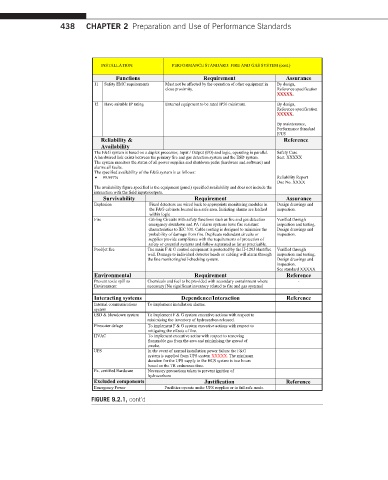

INSTALLATION: PERFORMANCE STANDARD: FIRE AND GAS SYSTEM (cont.)

Functions Requirement Assurance

11 Safety EMC requirements Must not be affected by the operation of other equipment in By design,

close proximity. Reference specification

XXXXX.

12 Have suitable IP rating External equipment to be rated IP56 minimum. By design,

Reference specification

XXXXX.

By maintenance,

Performance Standard

F/U5

Reliability & Reference

Availability

The F&G system is based on a duplex processor, Input / Output (I/O) and logic, operating in parallel. Safety Case

A hardwired link exists between the primary fire and gas detection system and the ESD system. Sect. XXXXX

The system monitors the status of all power supplies and shutdown paths (hardware and software) and

alarms all faults.

The specified availability of the F&G system is as follows:

∑ 99.997% Reliability Report

Doc No. XXXX

The availability figure specified is the equipment (panel) specified availability and does not include the

interaction with the field inputs/outputs.

Survivability Requirement Assurance

Explosion Fixed detectors are wired back to appropriate monitoring modules in Design drawings and

the F&G cabinets located in a safe area. Initiating alarms are latched inspection.

within logic

Fire Cabling Circuits with safety functions such as fire and gas detection Verified through

emergency shutdown and PA / alarm systems have fire resistant inspection and testing.

characteristics to IEC 331. Cable routing is designed to minimise the Design drawings and

probability of damage from fire. Duplicate redundant circuits or inspection.

supplies provide compliance with the requirements of protection of

safety or essential systems and follow separated as far as practicable.

Pool/jet fire The main F & G control equipment is protected by the H-120J blast/fire Verified through

wall. Damage to individual detector heads or cabling will alarm through inspection and testing.

the line monitoring/self-checking system. Design drawings and

inspection.

See standard XXXXX

Environmental Requirement Reference

Prevent toxic spill to Chemicals and fuel to be provided with secondary containment where -

Environment necessary [No significant inventory related to fire and gas systems]

-

Interacting systems Dependence/Interaction Reference

Internal communications To implement installation alarms.

system

ESD & blowdown system To implement F &G system executive actions with respect to

minimising the inventory of hydrocarbon released.

Firewater deluge To implement F & G system executive actions with respect to

mitigating the effects of fire.

HVAC To implement executive actins with respect to removing

flammable gas from the area and minimising the spread of

smoke.

UPS In the event of normal installation power failurethe F&G

system is supplied from UPS system XXXXX. The minimum

duration for the UPS supply to the HCS system is two hours

based on the TR endurance time.

Ex.certified Hardware Necessary precautions taken to prevent ignition of

hydrocarbons

Excluded components Justification Reference

Emergency Power Facilities operate under UPS supplies or in fail safe mode.

FIGURE 9.2.1, cont’d