Page 62 - Optofluidics Fundamentals, Devices, and Applications

P. 62

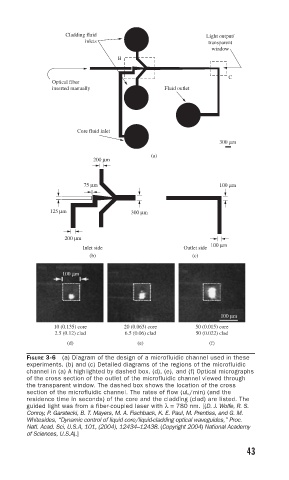

Cladding fluid Light output/

inlets transparent

window

B

C

Optical fiber

inserted manually Fluid outlet

Core fluid inlet

300 μm

(a)

200 μm

75 μm 100 μm

125 μm 300 μm

200 μm

100 μm

Inlet side Outlet side

(b) (c)

100 μm

100 μm

10 (0.135) core 20 (0.063) core 50 (0.015) core

2.5 (0.12) clad 6.5 (0.06) clad 50 (0.022) clad

(d) (e) (f)

FIGURE 3-6 (a) Diagram of the design of a microfluidic channel used in these

experiments. (b) and (c) Detailed diagrams of the regions of the microfluidic

channel in (a) A highlighted by dashed box. (d), (e), and (f) Optical micrographs

of the cross section of the outlet of the microfluidic channel viewed through

the transparent window. The dashed box shows the location of the cross

section of the microfluidic channel. The rates of flow (uL/min) (and the

residence time in seconds) of the core and the cladding (clad) are listed. The

guided light was from a fiber-coupled laser with λ= 780 nm. [(D. J. Wolfe, R. S.

Conroy, P. Garstecki, B. T. Mayers, M. A. Fischback, K. E. Paul, M. Prentiss, and G. M.

Whitesides, “Dynamic control of liquid core/liquid-cladding optical waveguides,” Proc.

Natl. Acad. Sci, U.S.A, 101, (2004), 12434–12438. (Copyright 2004) National Academy

of Sciences, U.S.A).]

43