Page 471 - Orlicky's Material Requirements Planning

P. 471

CHAPTER 26 Demand-Driven Planning 449

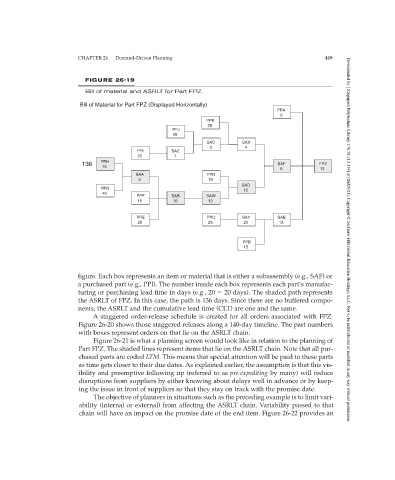

FIGURE 26-19

Bill of material and ASRLT for Part FPZ.

Bill of Material for Part FPZ (Displayed Horizontally)

PPA

5

PPK

20

PPJ

20

SAC SAX

3 4

PPI SAZ

25 7

PPH

136 SAF FPZ

75

6 13

SAA PPD

5 18

SAD

PPG 15

40

PPF SAB SAW

15 10 12

PPE PPC SAY SAE

20 25 20 13

PPB Downloaded by [ Singapore Polytechnic Library 176.79.113.174] at [06/05/21]. Copyright © McGraw-Hill Global Education Holdings, LLC. Not to be redistributed or modified in any way without permission.

15

figure. Each box represents an item or material that is either a subassembly (e.g., SAF) or

a purchased part (e.g., PPI). The number inside each box represents each part’s manufac-

turing or purchasing lead time in days (e.g., 20 20 days). The shaded path represents

the ASRLT of FPZ. In this case, the path is 136 days. Since there are no buffered compo-

nents, the ASRLT and the cumulative lead time (CLT) are one and the same.

A staggered order-release schedule is created for all orders associated with FPZ.

Figure 26-20 shows those staggered releases along a 140-day timeline. The part numbers

with boxes represent orders on that lie on the ASRLT chain.

Figure 26-21 is what a planning screen would look like in relation to the planning of

Part FPZ. The shaded lines represent items that lie on the ASRLT chain. Note that all pur-

chased parts are coded LTM. This means that special attention will be paid to these parts

as time gets closer to their due dates. As explained earlier, the assumption is that this vis-

ibility and preemptive following up (referred to as pre-expediting by many) will reduce

disruptions from suppliers by either knowing about delays well in advance or by keep-

ing the issue in front of suppliers so that they stay on track with the promise date.

The objective of planners in situations such as the preceding example is to limit vari-

ability (internal or external) from affecting the ASRLT chain. Variability passed to that

chain will have an impact on the promise date of the end item. Figure 26-22 provides an