Page 468 - Orlicky's Material Requirements Planning

P. 468

446 PART 4 Looking Backward and Forward

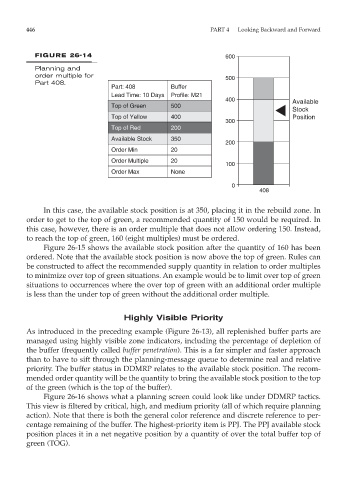

FIGURE 26-14 600

Planning and

order multiple for 500

Part 408.

Part: 408 Buffer

Lead Time: 10 Days Profile: M21

400 Available

Top of Green 500

Stock

Top of Yellow 400 Position

300

Top of Red 200

Available Stock 350

200

Order Min 20

Order Multiple 20

100

Order Max None

0

408

In this case, the available stock position is at 350, placing it in the rebuild zone. In

order to get to the top of green, a recommended quantity of 150 would be required. In

this case, however, there is an order multiple that does not allow ordering 150. Instead,

to reach the top of green, 160 (eight multiples) must be ordered.

Figure 26-15 shows the available stock position after the quantity of 160 has been

ordered. Note that the available stock position is now above the top of green. Rules can

be constructed to affect the recommended supply quantity in relation to order multiples

to minimize over top of green situations. An example would be to limit over top of green

situations to occurrences where the over top of green with an additional order multiple

is less than the under top of green without the additional order multiple.

Highly Visible Priority

As introduced in the preceding example (Figure 26-13), all replenished buffer parts are

managed using highly visible zone indicators, including the percentage of depletion of

the buffer (frequently called buffer penetration). This is a far simpler and faster approach

than to have to sift through the planning-message queue to determine real and relative

priority. The buffer status in DDMRP relates to the available stock position. The recom-

mended order quantity will be the quantity to bring the available stock position to the top

of the green (which is the top of the buffer).

Figure 26-16 shows what a planning screen could look like under DDMRP tactics.

This view is filtered by critical, high, and medium priority (all of which require planning

action). Note that there is both the general color reference and discrete reference to per-

centage remaining of the buffer. The highest-priority item is PPJ. The PPJ available stock

position places it in a net negative position by a quantity of over the total buffer top of

green (TOG).