Page 469 - Orlicky's Material Requirements Planning

P. 469

CHAPTER 26 Demand-Driven Planning 447

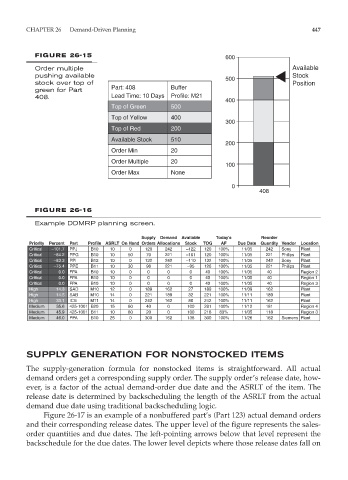

FIGURE 26-15 600

Order multiple Available

pushing available 500 Stock

stock over top of Position

green for Part Part: 408 Buffer

408. Lead Time: 10 Days Profile: M21

400

Top of Green 500

Top of Yellow 400

300

Top of Red 200

Available Stock 510

200

Order Min 20

Order Multiple 20

100

Order Max None

0

408

FIGURE 26-16

Example DDMRP planning screen.

Supply Demand Available Today’s Reorder

Priority Percent Part Profile ASRLT On Hand Orders Allocations Stock TOG AF Due Date Quantity Vendor Location

Critical –101.7 PPJ B10 10 0 120 242 –122 120 100% 11/05 242 Sony Plant

Critical –84.2 PPG B10 10 50 70 221 –101 120 100% 11/05 221 Philips Plant

Critical –83.3 PPI B12 10 0 132 242 –110 132 100% 11/05 242 Sony Plant

Critical –75.4 PPE B11 10 30 96 221 –95 126 100% 11/05 221 Philips Plant

Critical 0.0 FPA B10 10 0 0 0 0 40 100% 11/05 40 Region 2

Critical 0.0 FPA B10 10 0 0 0 0 40 100% 11/05 40 Region 1

Critical 0.0 FPA B10 10 0 0 0 0 40 100% 11/05 40 Region 3

High 14.3 SAD M10 12 0 189 162 27 189 100% 11/09 162 Plant

High 14.5 SAB M10 14 0 221 189 32 221 100% 11/11 189 Plant

High 33.1 ICB M11 14 0 242 162 80 242 100% 11/11 162 Plant

Medium 35.6 425-1001 B20 15 60 40 0 100 281 100% 11/12 181 Region 4

Medium 45.9 425-1001 B11 10 80 20 0 100 218 83% 11/05 118 Region 3

Medium 46.0 PPA B10 25 0 300 162 138 300 100% 11/26 162 Siemens Plant

SUPPLY GENERATION FOR NONSTOCKED ITEMS

The supply-generation formula for nonstocked items is straightforward. All actual

demand orders get a corresponding supply order. The supply order’s release date, how-

ever, is a factor of the actual demand-order due date and the ASRLT of the item. The

release date is determined by backscheduling the length of the ASRLT from the actual

demand due date using traditional backscheduling logic.

Figure 26-17 is an example of a nonbuffered part’s (Part 123) actual demand orders

and their corresponding release dates. The upper level of the figure represents the sales-

order quantities and due dates. The left-pointing arrows below that level represent the

backschedule for the due dates. The lower level depicts where those release dates fall on