Page 339 - Plastics Engineering

P. 339

322 Processing of Plastics

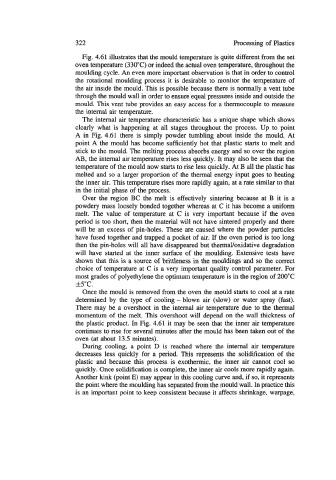

Fig. 4.61 illustrates that the mould temperature is quite different from the set

oven temperature (330°C) or indeed the actual oven temperature, throughout the

moulding cycle. An even more important observation is that in order to control

the rotational moulding process it is desirable to monitor the temperature of

the air inside the mould. This is possible because there is normally a vent tube

through the mould wall in order to ensure equal pressures inside and outside the

mould. This vent tube provides an easy access for a thermocouple to measure

the internal air temperature.

The internal air temperature characteristic has a unique shape which shows

clearly what is happening at all stages throughout the process. Up to point

A in Fig. 4.61 there is simply powder tumbling about inside the mould. At

point A the mould has become sufficiently hot that plastic starts to melt and

stick to the mould. The melting process absorbs energy and so over the region

AB, the internal air temperature rises less quickly. It may also be seen that the

temperature of the mould now starts to rise less quickly. At B all the plastic has

melted and so a larger proportion of the thermal energy input goes to heating

the inner air. This temperature rises more rapidly again, at a rate similar to that

in the initial phase of the process.

Over the region BC the melt is effectively sintering because at B it is a

powdery mass loosely bonded together whereas at C it has become a uniform

melt. The value of temperature at C is very important because if the oven

period is too short, then the material will not have sintered properly and there

will be an excess of pin-holes. These are caused where the powder particles

have fused together and trapped a pocket of air. If the oven period is too long

then the pin-holes will all have disappeared but thermaYoxidative degradation

will have started at the inner surface of the moulding. Extensive tests have

shown that this is a source of brittleness in the mouldings and so the correct

choice of temperature at C is a very important quality control parameter. For

most grades of polyethylene the optimum temperature is in the region of 200°C

43°C.

Once the mould is removed from the oven the mould starts to cool at a rate

determined by the type of cooling - blown air (slow) or water spray (fast).

There may be a overshoot in the internal air temperature due to the thermal

momentum of the melt. This overshoot will depend on the wall thickness of

the plastic product. In Fig. 4.61 it may be seen that the inner air temperature

continues to rise for several minutes after the mould has been taken out of the

oven (at about 13.5 minutes).

During cooling, a point D is reached where the internal air temperature

decreases less quickly for a period. This represents the solidification of the

plastic and because this process is exothermic, the inner air cannot cool so

quickly. Once solidification is complete, the inner air cools more rapidly again.

Another kink (point E) may appear in this cooling curve and, if so, it represents

the point where the moulding has separated from the mould wall. In practice this

is an important point to keep consistent because it affects shrinkage, warpage,