Page 124 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 124

A New Do11ain and More Process Models 99

Answer The most phase lag that can come out of a first-order process is 90°

and that is only at high frequencies. Proportional-only control adds no phase

lag and integral-only adds 90° so the first-order process under integral-only or

proportional-integral control can only have 180° phase lag as a limiting case

when the frequency is extremely high.

4-4 A Pure Dead-Time Process

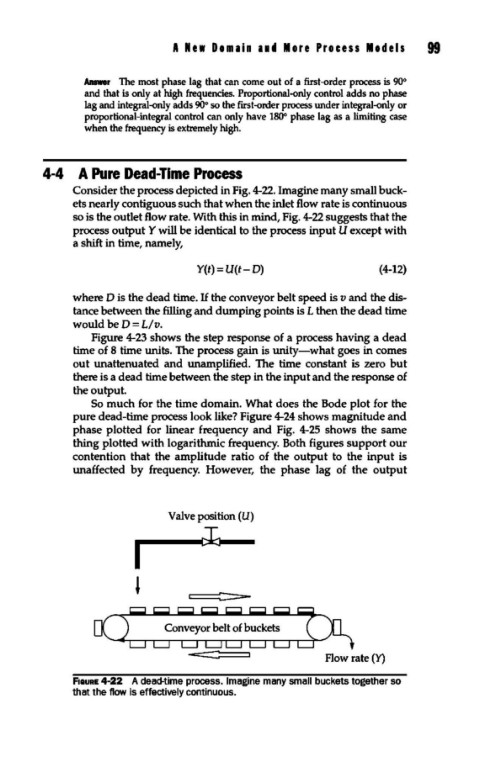

Consider the process depicted in Fig. 4-22. Imagine many small buck-

ets nearly contiguous such that when the inlet flow rate is continuous

so is the outlet flow rate. With this in mind, Fig. 4-22 suggests that the

process output Y will be identical to the process input U except with

a shift in time, namely,

Y(t) = U(t- D) (4-12)

where D is the dead time. If the conveyor belt speed is v and the dis-

tance between the filling and dumping points is L then the dead time

would beD= L/v.

Figure 4-23 shows the step response of a process having a dead

time of 8 time units. The process gain is unity-what goes in comes

out unattenuated and unamplified. The time constant is zero but

there is a dead time between the step in the input and the response of

the output.

So much for the time domain. What does the Bode plot for the

pure dead-time process look like? Figure 4-24 shows magnitude and

phase plotted for linear frequency and Fig. 4-25 shows the same

thing plotted with logarithmic frequency. Both figures support our

contention that the amplitude ratio of the output to the input is

unaffected by frequency. However, the phase lag of the output

Valve position (U)

~

'

Flow rate (Y)

F1auRE 4-22 A dead-time process. Imagine many small buckets together so

that the flow is effectively continuous.