Page 127 - Rashid, Power Electronics Handbook

P. 127

114 S. Abedinpour and K. Shenai

shown in Fig. 7.20. The IGBTS have been introduced at high

voltage and current levels, which has enabled their use in high-

power converters utilized for medium-voltage motor drives.

The improved characteristics of the IGBTs have introduced

power converters in megawatt power applications such as

traction drives. One of the critical issues in realizing high-

power converters is the reliability of the power switches. The

devices used in these applications must be robust and capable FIGURE 7.19 IGBT welder.

of withstanding faults long enough for a protection scheme to

be activated. The hard-switching voltage source power conver-

ter is the most commonly used topology. In this switch-mode

operation the switches are subjected to high switching stresses snubber circuits achieve this goal without the added control

and high-switching power loss that increase linearly with the complexity, but the power dissipation in these snubber circuits

switching frequency of the pulsewidth modulation (PWM). can be large and limit the switching frequency of the converter.

The resulting switching loci in the v ÿ i plane is shown by Also, passive components signi®cantly add to the size, weight,

t t

the dotted lines in Fig. 7.11. Because of simultaneous large and cost of the converter at high power levels. Soft switching

switch voltage and large switch current, the switch must be uses lossless resonant circuits, which solves the problem of

power loss in the snubber circuit, but increases the conduction

capable of withstanding high switching stresses with a large

loss. Resonant transition circuits eliminate the problem of

SOA. The requirement of being able to withstand large stresses

high peak device stress in the soft-switched converters. The

results in design compromises in other characteristics of the

main drawback of these circuits is the increased control

power semiconductor device. Often forward voltage drop and

complexity required to obtain the resonant switching transi-

switching speed are sacri®ced for enhanced short-circuit

tion. The large number of circuit variables to be sensed in such

capability. Process parameters of the IGBT such as threshold

power converters can affect their reliability. With short-circuit

voltage, carrier lifetime, and the device thickness can be varied

capability no longer being the primary concern, designers can

to obtain various combinations of SOA, on-state voltage, and

push the performance envelope for their circuits until the

switching time. However, there is very little overlap in the

device becomes the limiting factor once again.

optimum combination for more than one performance para-

The transient response of the conventional volts=hertz

meter. Therefore, improved performance in one parameter is

induction motor drive is sluggish because both torque and

achieved at the cost of other parameters.

¯ux are functions of stator voltage and frequency. Use of

In order to reduce the size, the weight, and the cost of

circuit components used in a power electronics converter very vector or ®eld-oriented control methods makes the perfor-

high switching frequencies of the order of a few megahertz are mance of the induction motor drive almost identical to that of

being contemplated. In order to be able to increase the a separately excited dc motor. Therefore, the transient

switching frequency, the problems of switch stresses, switching response is similar to a dc machine, where torque and ¯ux

losses and the EMI associated with switch-mode applications can be controlled in a decoupled manner. Vector-controlled

need to be solved. Use of soft-switching converters reduces the induction motors with shaft encoders or speed sensors have

problems of high dv=dt and high di=dt by use of external been widely applied in combination with voltage-source PWM

inductive and capacitive components to shape the switching inverters using IGBT modules. According to the speci®cation

trajectory of the device. The device-switching loci resulting of the new products, vector-controlled induction motor drive

systems ranging from kilowatts to megawatts provide a broad

from soft switching is shown in Fig. 7.11, where signi®cant

range of speed control, constant torque operation, and high

reduction in switching stress can be noticed. The traditional

starting torque.

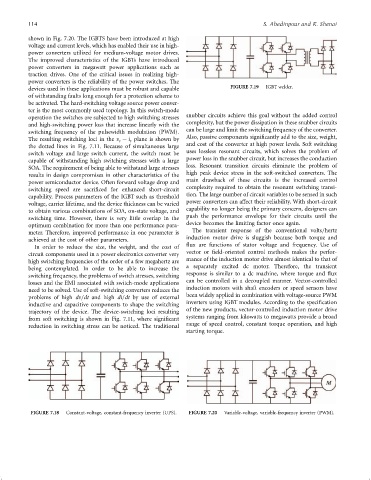

FIGURE 7.18 Constant-voltage, constant-frequency inverter (UPS). FIGURE 7.20 Variable-voltage, variable-frequency inverter (PWM).