Page 446 - Robot Builder's Bonanza

P. 446

MAKING PERMANENT CIRCUITS ON SOLDER BREADBOARDS 415

• Custom prototyping boards. Some components with “rock star” status (most notably,

microcontrollers like the PICAXE, AVR, and PICMicro) have various custom prototyping

boards available for them. Take your pick.

• Wire wrapping. Semipermanent construction using very thin wire between components.

You can undo the wires to make changes.

There are other methods that I’ll be skipping here. Many are out of date, are specific to

one manufacturer, require hard- to- find parts, or may require special tools.

Clean It First!

Circuit boards use a thin layer of copper to form traces, the wires of the circuit. Copper can

oxidize and get dirty over time, both of which can lead to a poor solder joint. No matter which

circuit- board- making method you use, prior to any soldering be sure to thoroughly clean the

board using warm water and ordinary kitchen cleansing powder. You can scrub the board

using your fingers, a folded- up paper towel, or a nonmetallic scouring pad.

After cleaning, rinse all of the cleanser off the board. Pat it dry with a paper towel, then

let it air- dry— it takes a couple of minutes. For a superclean board, wet a cotton ball with

household isopropyl alcohol and give the metal a final wipedown. Allow all of the alcohol to

evaporate.

Making Permanent Circuits

on Solder Breadboards

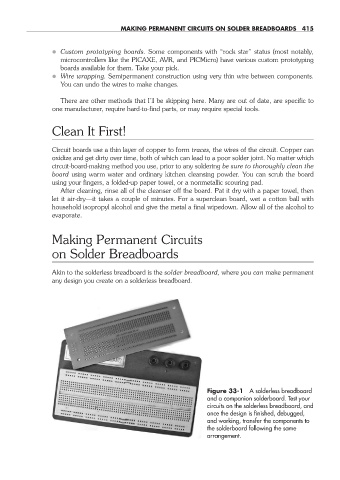

Akin to the solderless breadboard is the solder breadboard, where you can make permanent

any design you create on a solderless breadboard.

Figure 33- 1 A solderless breadboard

and a companion solderboard. Test your

circuits on the solderless breadboard, and

once the design is finished, debugged,

and working, transfer the components to

the solderboard following the same

arrangement.

33-chapter-33.indd 415 4/21/11 11:56 AM