Page 205 - Separation process principles 2

P. 205

170 Chapter 5 Cascades and Hybrid Systems

Makeup

absorbent Makeup

1 I I absorbent

+-

Absorber

-III-I Stripper Absorber

Entering

Entering

vapor (e.g., steam or

other inert gas) vapor

,

Recycle absorbent

Recycle absorbent

Makeup

q

absorbent

-

Absorber

Entering

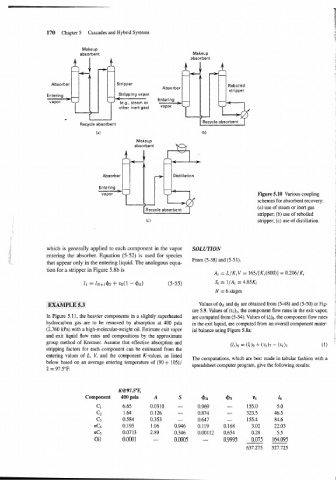

vapor Figure 5.10 Various coupling

. schemes for absorbent recovery:

f

Recycle absorbent (a) use of steam or inert gas

stripper; (b) use of reboiled

stripper; (c) use of distillation.

which is generally applied to each component in the vapor SOLUTION

entering the absorber. Equation (5-52) is used for species

From (5-38) and (5-51),

that appear only in the entering liquid. The analogous equa-

tion for a stripper in Figure 5.8b is

Ai = L/Ki V = 165/[Ki(800)] = 0.206/K1

11 = ~N+I$S + vo(1 - $A) (5-55) Si = 1/A; = 4.85Ki

N = 6 stages

Values of $A and are obtained from (5-48) and (5-50) or Fig-

ure 5.9. Values of (v,),, the component flow rates in the exit vapor,

In Figure 5.11, the heavier components in a slightly superheated are computed from (5-54). Values of the component flow rates 1

hydrocarbon gas are to be removed by absorption at 400 psia in the exit liquid, are computed from an overall component mater- !

(2,760 kPa) with a high-molecular-weight oil. Estimate exit vapor ial balance using Figure 5.8a:

and exit liquid flow rates and compositions by the approximate

i

group method of Kremser. Assume that effective absorption and

(1116 = (&)o + (21117 - (vi)1 (1)

stripping factors for each component can be estimated from the

entering values of L, V, and the component K-values, as listed

The computations, which are best made in tabular fashion with a

below based on an average entering temperature of (90 + 105)/

spreadsheet computer program, give the following results:

2 = 97.5"F.

K@97.S°F,

Component 400 psia

c 1 6.65

c2 1.64

c3 0.584

nC4 0.195

nCs 0.0713

Oil 0.0001