Page 232 - Separation process principles 2

P. 232

6.1 Equipment 197

-r--

Plate

Vapor flow Vapor flow Vapor flow ,

(a) (b) (c)

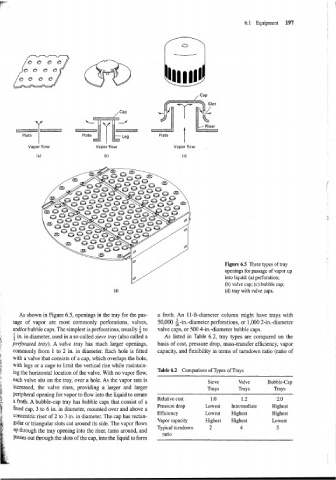

Figure 6.5 Three types of tray

openings for passage of vapor up

into liquid: (a) perforation;

(b) valve cap; (c) bubble cap;

(d) tray with valve caps.

As shown in Figure 6.5, openings in the tray for the pas- a froth. An 11-ft-diameter column might have trays with

sage of vapor are most commonly perforations, valves, 50,000 A-in.-diameter perforations, or 1,000 2-in.-diameter

and/or bubble caps. The simplest is perforations, usually to valve caps, or 500 4-in.-diameter bubble caps.

in. in diameter, used in a so-called sieve tray (also called a As listed in Table 6.2, tray types are compared on the

perforated tray). A valve tray has much larger openings, basis of cost, pressure drop, mass-transfer efficiency, vapor

commonly from 1 to 2 in. in diameter. Each hole is fitted capacity, and flexibility in terms of turndown ratio (ratio of

with a valve that consists of a cap, which overlaps the hole,

with legs or a cage to limit the vertical rise while maintain-

Table 6.2 Comparison of Types of Trays

ing the horizontal location of the valve. With no vapor flow,

each valve sits on the tray, over a hole. As the vapor rate is Sieve Valve Bubble-Cap

mcreased, the valve rises, providing a larger and larger Trays Trays Trays

Peripheral opening for vapor to flow into the liquid to create

Relative cost 1 .O 1.2 2.0

a froth. A bubble-cap tray has bubble caps that consist of a

Pressure drop Lowest Intermediate Highest

fixed cap, 3 to 6 in. in diameter, mounted over and above a

Efficiency Lowest Highest Highest

concentric riser of 2 to 3 in. in diameter. The cap has rectan-

Vapor capacity Highest Highest Lowest

gular or triangular slots cut around its side. The vapor flows

Typical turndown 2 4 5

UP through the tray opening into the riser, turns around, and

ratio

Passes out through the slots of the cap, into the liquid to form