Page 234 - Separation process principles 2

P. 234

6.1 Equipment 199

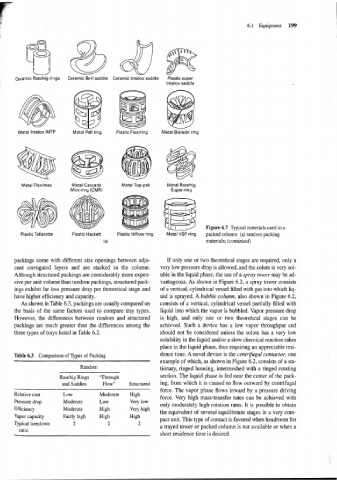

Ceramic Raschig rings Ceramic Berl saddle Ceramic lntalox saddle Plastic super

lntalox saddle

Metal lntalox IMTP Metal Pall ring Plastic Flexiring Metal Bialecki ring

Metal Fleximax Metal Cascade Metal Top-pak Metal Raschig

Mini-ring (CMR) Super-ring

Figure 6.7 Typical materials used in a

Plastic Tellerette Plastic Hackett Plastic Hiflow ring Metal VSP ring packed column: (a) random packing

(a) materials; (continued)

paclungs come with different size openings between adja- If only one or two theoretical stages are required, only a

cent corrugated layers and are stacked in the column. very low pressure drop is allowed, and the solute is very sol-

Although structured packings are considerably more expen- uble in the liquid phase, the use of a spray tower may be ad-

sive per unit volume than random packings, structured pack- vantageous. As shown in Figure 6.2, a spray tower consists

ing~ exhibit far less pressure drop per theoretical stage and of a vertical, cylindrical vessel filled with gas into which liq-

have higher efficiency and capacity. uid is sprayed. A bubble column, also shown in Figure 6.2,

As shown in Table 6.3, packings are usually compared on consists of a vertical, cylindrical vessel partially filled with

the basis of the same factors used to compare tray types. liquid into which the vapor is bubbled. Vapor pressure drop

However, the differences between random and structured is high, and only one or two theoretical stages can be

packings are much greater than the differences among the achieved. Such a device has a low vapor throughput and

three types of trays listed in Table 6.2. should not be considered unless the solute has a very low

solubility in the liquid and/or a slow chemical reaction takes

place in the liquid phase, thus requiring an appreciable resi-

Table 6.3 Comparison of Types of Packing dence time. A novel device is the centrifugal contactor, one

example of which, as shown in Figure 6.2, consists of a sta-

Random tionary, ringed housing, intermeshed with a ringed rotating

Raschig Rings "Through section. The liquid phase is fed near the center of the pack-

and Saddles Flow" Stmctured ing, from which it is caused to flow outward by centrifugal

force. The vapor phase flows inward by a pressure driving

Relative cost Low Moderate High

force. Very high mass-transfer rates can be achieved with

Pressure drop Moderate Low Very low

only moderately high rotation rates. It is possible to obtain

Efficiency Moderate High Very high

the equivalent of several equilibrium stages in a very com-

Vapor capacity Fairly high High High

pact unit. This type of contact is favored when headroom for

Typical turndown 2 2 2 a trayed tower or packed column is not available or when a

ratio

short residence time is desired.